Overview

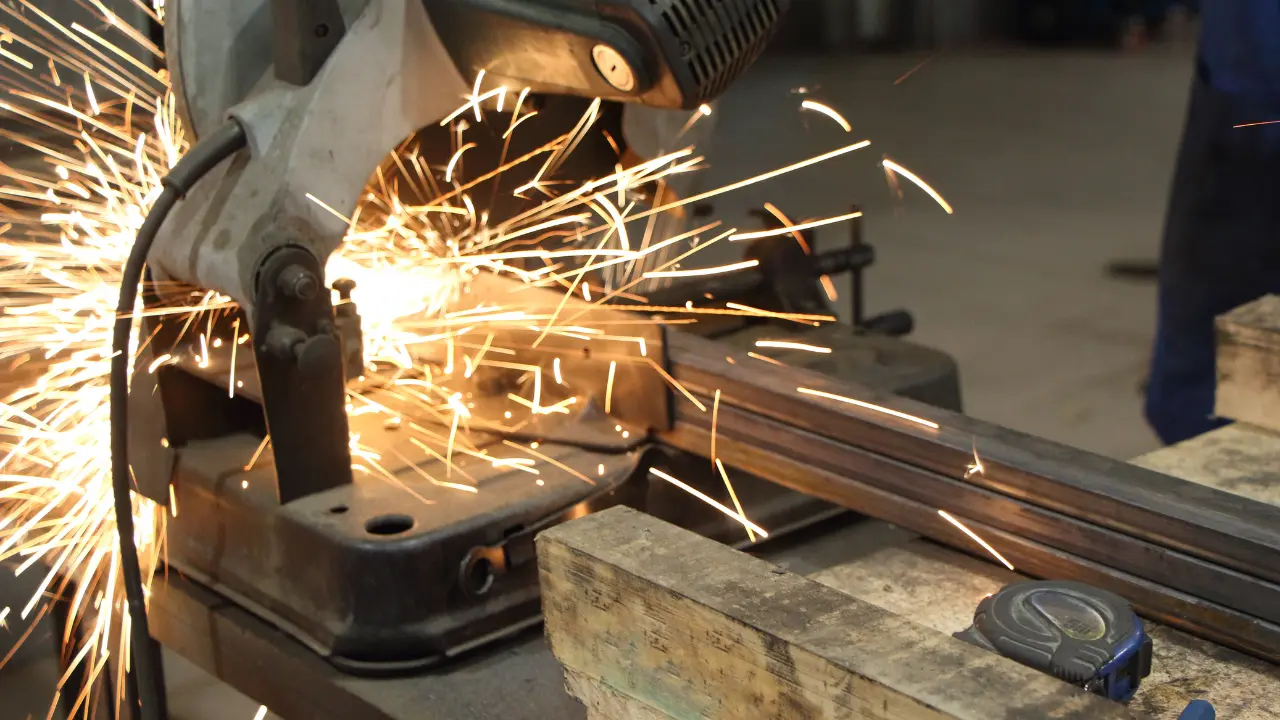

CNC automation often plays a critical role in manufacturing processes and scalability. CNC automation circumvents the use of human intervention in manufacturing processes and allows for greater efficiencies in manufacturing.

SolidCAD offers a full process automation service customized to your unique CNC machining setup. This supports our CNC machining services, including CNC post processor programming, machine simulation tools, and OMV implementation to provide functional and optimized CNC milling and machining processes.

With most of SolidCAD’s consulting services, our CNC automation services provide a custom product to reduce friction in your production line.

Why You Need Custom CNC Automation

Most worksites need a custom solution that integrates CAD and CAM systems, allowing the automatic generation of toolpaths and G-code from CAD models.

By applying our CNC automation solutions in your worksites, SolidCAD can streamline your CNC programming process, reducing the manual effort and time required to prepare CNC programs.

Working with a skilled consultant like SolidCAD gives your manufacturing business access to machine tool simulation and process verification. You can also access our advanced manufacturing solutions for programming robotic arms for tasks like machining, additive manufacturing (3D printing), or a combination of both (hybrid manufacturing).

Our custom process can also be applied in CNC machined parts processes. Your system requires precision and accuracy for a machined part to meet very tight tolerances, especially in industries like aerospace, automotive, medical, and defence, where the exact dimensions and quality of each component can significantly impact the performance and safety of the final product.

By working with SolidCAD for custom CNC machining, you can automate and streamline numerous programming processes, enhancing your machining efficiency and minimizing errors.

Custom CNC Automation Capabilities

SolidCAD’s CNC automation capabilities include standard features like full 5-axis programming, an essential feature in CNC mill systems that machine complex shapes and geometries, and automatic collision avoidance for toolpath optimization and collision prevention.

SolidCAD can assist you with quickly generating NC (Numerical Control) code for various types of machining processes, including high-speed 3-axis machining, 3+2 programming (which combines 3-axis milling with two additional axes of rotation for positioning), 2.5D milling (involving cuts along two axes with incremental depth), and turning.

This versatility supports a wide range of manufacturing applications. SolidCAD CNC automation capabilities also include:

- Full process automation and optimization of PowerMill Standard programming

- Access to full 5-axis programming with automatic collision avoidance, machine simulation, robot programming, automated electrodes, hybrid manufacturing, and more

- Enhanced verification features ensure that tool changes and laser checks are accurately positioned

- Automation for the design and manufacturing of electrodes used in processes like EDM (Electrical Discharge Machining).

- CNC automation for queue of projects and batch processing, ideal for lights-out manufacturing setups

- Automation for complex geometries, advanced mills, and multiple machines

Benefits of Choosing SolidCAD

CNC Automation encompasses a broad range of technologies and software solutions because you need a seamless and efficient workflow from design to finished product.

SolidCAD consulting, combined with the power of software like PowerMill and Fusion 360, helps stabilize the manufacturing process by providing consistent and optimized toolpaths, reducing the chance of tooling errors, and ensuring high-quality output. We know this is especially important in machined parts, which require precision and reduced alteration during the machining process.

In an automated CNC production environment, the machining operations are automated, but so too is the transfer of parts between different stages of the manufacturing process.

Whether this includes automated loading and unloading of the CNC machine (robotic machine tending), automated assembly, robots for material handling, or conveyor systems for moving parts, SolidCAD experts can generate efficient toolpaths for your custom machining that not only ensure a smooth production run but also quality control within the broader automation system.

Our Recent Success

These real-life cases illustrate how we’ve empowered businesses to streamline their operations, breaking down silos and enhance interdepartmental communication. Each story is a testament to how our strategic approach has not only solved complex issues but paved the way for seamless and productive workflows.

Resources

Featured

Blogs

Additional resources

Trust SolidCAD Today Custom Automation Solution

As businesses grow and technologies evolve, the needs of a worksite will change.

Whether you’re in aerospace, fabrication, CNC milling, or industrial automation, SolidCAD’s custom automation for your CNC machining service is the right choice. Our services include rapid NC code creation, advanced 5-axis programming, robot programming, and batch calculation for lights-out operations, all of which are integral to modern CNC automation systems, providing a high degree of precision, flexibility, and efficiency in manufacturing processes.

We also ensure that your CNC system integration provides a seamless flow of data and operations from CAD design to CAM programming and finally to CNC machining.

With access to our expertise and vast capabilities, manufacturers can plan their machining operations more effectively, taking into account machine availability, tool usage, and material requirements, thereby maximizing efficiency and throughput.