Overview

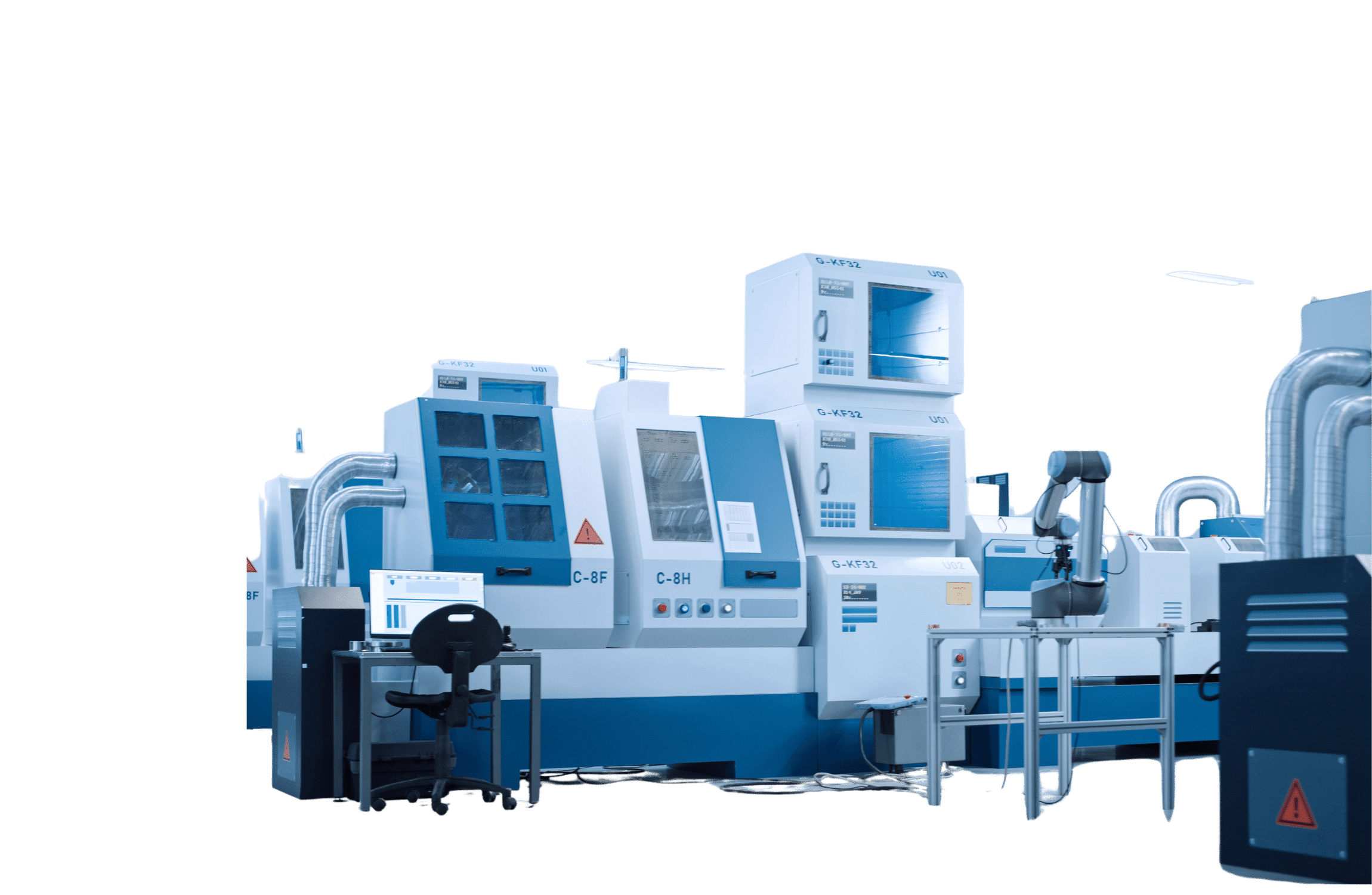

A custom CAM integration setup for robotics and CNC machining brings together the best of design and manufacturing, leading to a highly efficient, precise, and flexible production environment.

Each CNC robotic cell is unique, with specific requirements based on the types of parts being manufactured, the materials used, and the desired throughput.

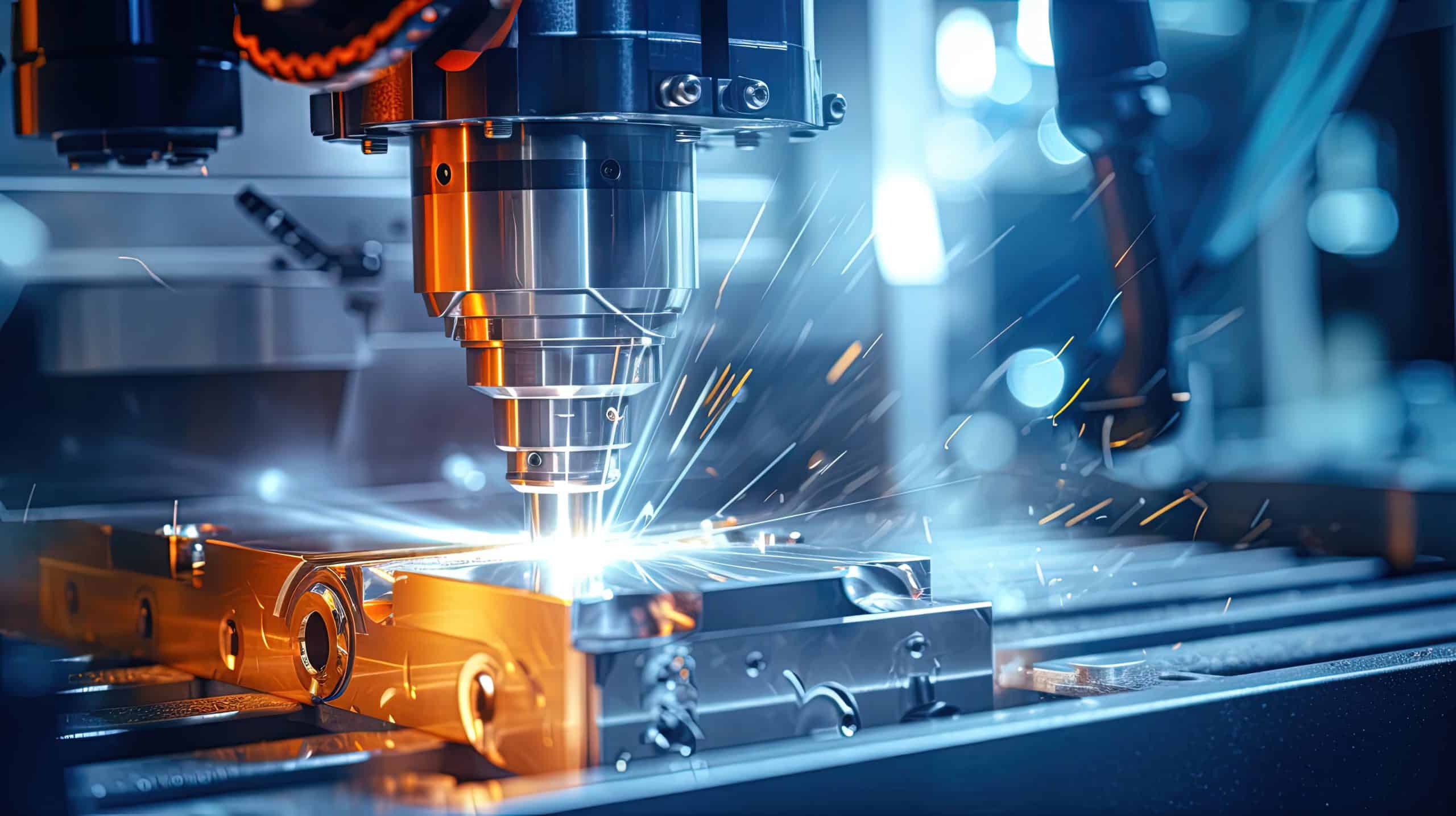

Our programming allows for the accuracy and customization of robotic movements, machine settings, and operational sequences to optimize the cell for specific tasks, whether it’s for high-precision machining, rapid prototyping, or high-volume production.

Why You Need Custom CNC Robot Cell Set-Up

Setting up a CNC robot cell involves integrating a robotic system with CNC machines and auxiliary equipment to create an automated manufacturing or machining environment.

A custom solution will ensure seamless communication and data exchange between different machining components and the CNC robot cells, ensuring these automatons are designed specifically for your manufacturing setup.

Custom CAM integration also ensures that each part is machined with high precision, closely adhering to the original design specifications. This consistency is crucial for industries requiring high-quality and precision parts, such as aerospace and medical devices.

Custom CNC Robot Cell Set-Up Capabilities

Custom CAM integration allows for the creation of optimized machining paths, and it is almost always required in a CNC robot cell set-up as every manufacturing process is different.

Doing so allows for easy adjustments and modifications to designs, which can be quickly implemented in the machining process. This adaptability is essential in innovative manufacturing and prototyping, where designs may frequently change.

With SolidCAD’s consulting, you can design or select suitable end-of-arm tooling for the robot to interact with the CNC machines, ensuring that they can perform the required tasks with the necessary precision and safety, whether it’s picking and placing (machine tending), machining, or complex assembly tasks.

SolidCAD can also design an efficient workflow that integrates CNC machines with robotic systems, ensuring smooth transitions and minimizing bottlenecks. This might involve setting up a robot cell that includes not just the machining operations but also ancillary tasks such as material handling, part inspection, and finishing processes.

Benefits of Choosing SolidCAD

By choosing SolidCAD’s custom consultant service to set up an integrated robotics and CNC machining environment are substantial, you gain access to a deep knowledge of the CAM software development team.

Experience in the CAM industry is especially important when considering the diversity and complexity of applications involved in CNC machining and robot cell programming.

Whether it is industrial robots, robot arms, collaborative robots, or other machine types within machine shops and the broader manufacturing industry, SolidCAD can help.

SolidCAD brings in-depth knowledge across a range of applications, from simple robotic grippers to complex mobile robots and high-precision inspection systems.

Our industry expertise ensures that each aspect of the robotic system, from payload capacities to end-of-arm tooling, is selected and integrated to meet the exact requirements of your machining operations.

SolidCAD can also help plan and implement a system that not only meets current needs but is also scalable and flexible enough to accommodate future expansion or adaptation to new processes, materials, or products, this includes milling and complex machining.

Our Recent Success

These real-life cases illustrate how we’ve empowered businesses to streamline their operations, breaking down silos and enhance interdepartmental communication. Each story is a testament to how our strategic approach has not only solved complex issues but paved the way for seamless and productive workflows.

Resources

Featured

Blogs

Additional resources

Trust SolidCAD Today

SolidCAD can offer solutions that are precisely tailored to your unique setup, ensuring that the integration or adaptation of robotic systems, whether they are a stationary industrial robot, a versatile robot arm, or a collaborative robot designed for safe human-robot interaction, is optimized for your specific manufacturing processes and goals.

With our other CNC services, you can tap into full CNC workflow design, shop floor job tracking, and robotic automation.

Beyond the initial setup, SolidCAD CNC automation experts can provide comprehensive training to your staff, ensuring they are equipped to operate, maintain, and troubleshoot the integrated system effectively.

SolidCAD ensures that the robotic and CNC integration complies with industry standards and safety regulations, reducing the risk of accidents and ensuring the safety of personnel.