Overview

At SolidCAD, we specialize in developing custom IoT or Internet of Things solutions, utilizing Microsoft technologies, specifically IoT Central, to enable you to monitor and report on various metrics critical to your business.

Why You Need SolidCAD IoT Services

In the realm of building management, precise metrics are the key to efficiency. SolidCAD’s IoT customizations enable you to monitor and report on crucial aspects such as airflow and lighting.

With our custom software development services for IoT, you gain real-time visibility into building performance, allowing for proactive adjustments to enhance energy efficiency, comfort, and overall operational effectiveness.

Our IoT developer services can support your digital transformation strategy, whether you are interested in IoT monitoring for manufacturing or an IoT hub to streamline your processes.

We understand that every business is unique, and not all your IoT devices will operate perfectly with out-of-the-box solutions. Leverage custom software development to bring your business to the next level.

SolidCAD's IoT Features

By harnessing Microsoft technologies, particularly IoT Central, SolidCAD provides a comprehensive suite of tools for real-time monitoring and analysis.

This suite is designed to offer businesses a granular view of their operational metrics, be it in building management or manufacturing efficiency, allowing for informed decision-making and real-time data.

Real-Time Monitoring

Gain instant visibility into critical metrics, allowing for proactive decision-making and improved operational efficiency.

Customized Dashboards

Tailor dashboards to your specific needs, ensuring that the information most relevant to your business is readily accessible.

Predicitive Analytics

Leverage the power of data to predict trends and potential issues, allowing you to implement preventive measures and avoid disruptions.

Scalability

Our IoT solutions are designed to scale with your business, accommodating growth and evolving requirements seamlessly.

Unprecedented Connectivity

Leverage IoT to connect sensor information to CAD models.

Our IoT Service Capabilities

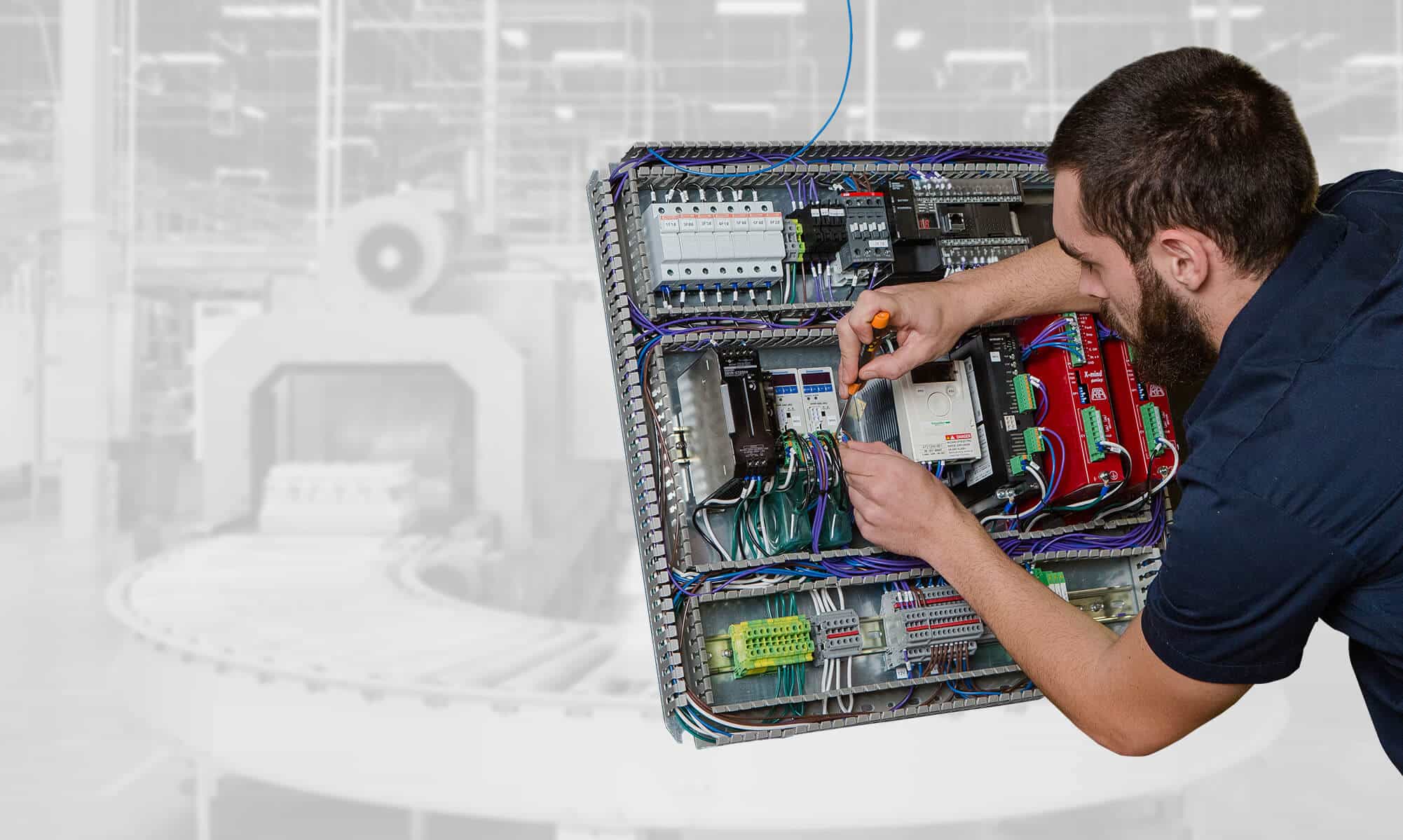

Smart Manufacturing and Digital Twins

Using CAD models to create digital twins of manufacturing equipment or entire production lines, which are then integrated with IoT sensors to monitor performance, predict maintenance needs, and optimize operations in real-time. This integration allows for the simulation of manufacturing processes in the digital twin.

Building Information Modeling (BIM) and Smart Buildings

Integrating CAD-based BIM models with IoT sensors installed in buildings to monitor and manage various parameters such as energy usage, occupancy levels, temperature, and air quality. This can help facility managers optimize energy consumption, improve occupant comfort, and enhance building maintenance by providing real-time data linked directly to the BIM model, facilitating informed decision-making.

Product Lifecycle Management (PLM)

Integrate IoT data from products in use with their corresponding CAD models and PLM data. This allows manufacturers to track the performance and usage patterns of their products in real time, providing valuable feedback that can be used to inform future design improvements, predict maintenance schedules, and even innovate new product features based on actual user behavior.

Adaptive and Responsive Infrastructure

Designing infrastructure projects such as bridges or roads with CAD software and integrating these designs with IoT sensors that monitor structural health, traffic flow, and environmental conditions. This data can be used to predict maintenance needs, inform traffic management systems, and even adapt the infrastructure in real time to changing conditions, such as dynamically adjusting lighting or signage to improve safety and efficiency.

Remote Monitoring and Control of Industrial Equipment

CAD equipment that has IoT sensors can be connected to our IoT hub for remote monitoring and control. This enables operators to visualize the equipment’s operational status in real-time, perform remote diagnostics, and even control the equipment from a distance, reducing the need for onsite visits and improving operational efficiency. Access this data from a mobile app, dashboard, or central console.

Benefits of SolidCAD Custom IoT Consulting Services

SolidCAD leverages Microsoft technologies, with a focus on IoT Central, to build robust and scalable IoT solutions tailored to your unique needs.

IoT Central provides a unified platform for IoT applications, offering seamless integration with your CAD data and other data sources for simplified management, and unparalleled flexibility.

Our team of experts ensures that your IoT customizations align with your business goals, delivering insights that drive tangible results.

Microsoft Partnership

As a Microsoft-focused firm, we bring extensive experience in harnessing the capabilities of Microsoft technologies, ensuring your IoT solutions are built on a robust foundation.

Industry Expertise

SolidCAD understands the unique challenges of various industries, tailoring IoT development to address specific needs in building management and manufacturing.

Proven Track Record

Our history of successful IoT implementations speaks to our commitment to delivering solutions that make a tangible impact on operational efficiency.

Our Recent Success

These real-life cases illustrate how we’ve empowered businesses to streamline their operations, breaking down silos and enhance interdepartmental communication. Each story is a testament to how our strategic approach has not only solved complex issues but paved the way for seamless and productive workflows.

Resources

Featured

Blogs

Additional resources

Trust SolidCAD for IoT Software Development

Ready to embrace the transformative power of IoT monitoring and real-time metrics?

Contact SolidCAD to explore how our IoT software development services can enhance your operations, providing real-time insights and empowering you to make data-driven decisions.

Experience a connected future with SolidCAD as your trusted IoT partner.