Success Stories

3D-P

3D-P consists of a team of mining and positioning technology experts. It was created to bring innovative thinking and new technologies to the mining industry. They have since evolved to bring this approach to several outdoor industrial environments around the world. They continue to work hard to understand the unique environments their clients are working in and the unique needs their operations have.

Streamlining workflows and improving data management with Fusion 360 Manage!

The Challenge

After investigation of their issues, 3D-P identified two specific areas they wanted to improve; (1) the inefficient design management that relied heavily on manual data entry, and outdated practices for managing their Bill of Materials (BOMs) and (2) challenges of change management and communication. As the company grew, they realized that a lot of their processes were slowing them down and needed to be optimized.

Particularly, they were able to identify their need for a redefined workflow and sought out a PLM strategy that would help them better share and collaborate their BOMs with other departments from design to manufacturing and improve the way they managed their regulatory documents. They wanted to have the ability to quickly identify documents that were related to a specific component in their products, rather than manually digging up information.

Their goal was to have a centralized system that would help them identify changes and communicate them effectively with other parties involved. After diligently investigating six different platforms, they reached out to the SolidCAD team to help them on their journey to success.

The Solution

Partnering with SolidCAD’s Enterprise Team, 3D-P decided to proceed with an implementation of Autodesk’s Fusion 360 Manage. The solution enabled them to achieve efficiency and control of their BOM’s, documentation and change control processes. Working with SolidCAD gave them access to the expertise needed, ensuring the solution would be designed to achieve their goals.

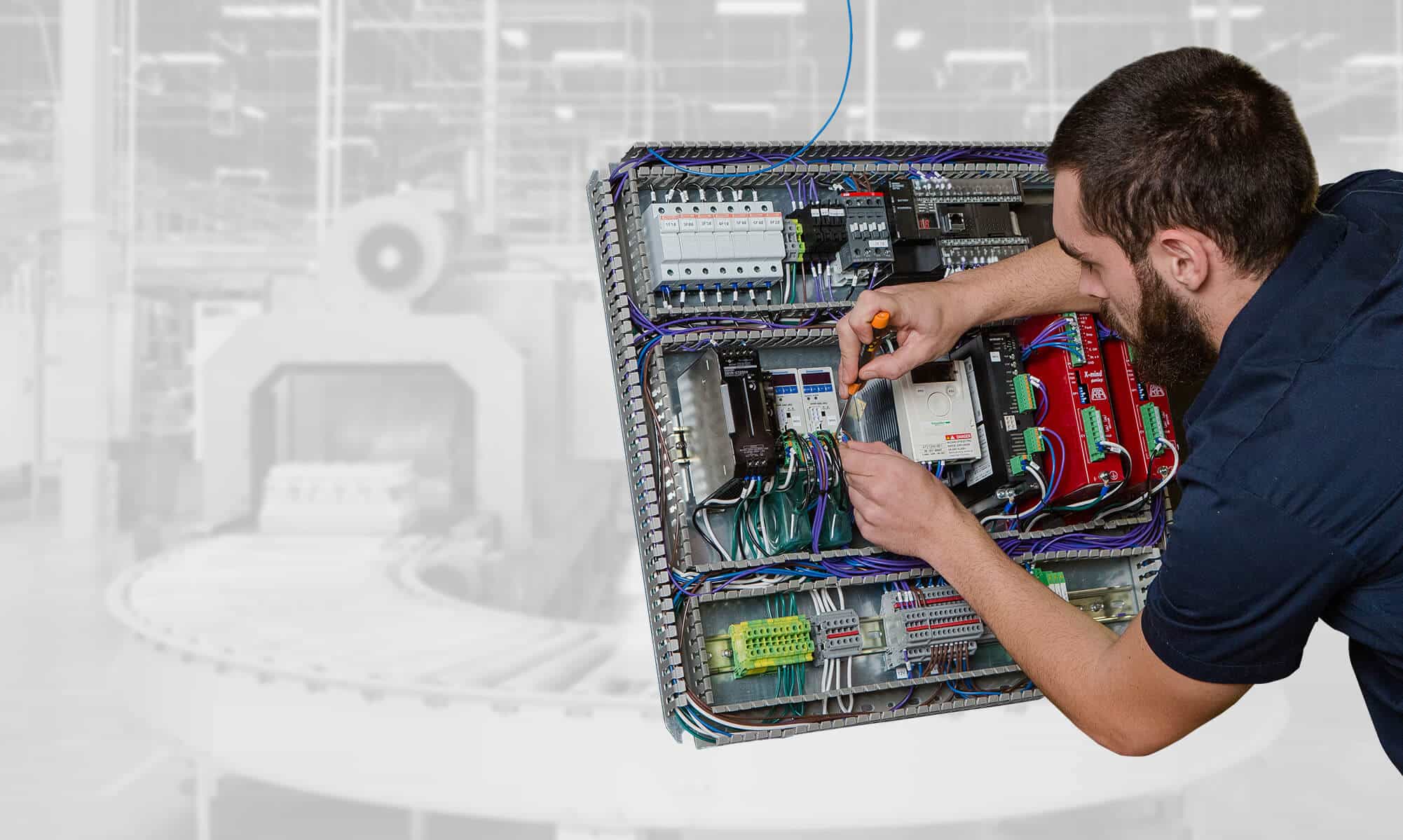

The BOM management feature in Fusion 360 Manage helped 3D-P to have more structured process when they create, modify, and manage both their electrical and mechanical BOMs. Since Autodesk PLM solution is in the cloud, 3D-P’s manufacturing team always had access to the latest information. The company was able keep track of their changes and more importantly identify the business areas that required improvements. Since the change and BOM environments in PLM are connected, 3D-P was able to take advantage of the revision control and easily keep track of their product changes.

As an added bonus, team members within their engineering department were already familiar with Autodesk products and adapted to the implementation of their new software with a shortened learning curve.

The Results

- Fusion 360 Manage is now their single source of truth. While they previously spent a lot of time consulting various departments and team members to verify data, the information is now in one central location, easily managed by their engineering manager.

- Their change management is now more ergonomic and practical. Team members are notified of any changes or updates, ensuring everyone is working with the latest data.

- It now takes their team a third of the time to manage BOMs.

- Overall, they save 7-10 hours of rework that would often be due to human error in their design and engineering data.

Testimonial

One of our core values as a company is that relationships matter. We’re all about building relationships with our customers and working to enable their success. The tool on its own is one thing but in order to be successful, you want someone who can be a good partner and that’s what SolidCAD has been from the beginning. You want a partner that understands the importance of that relationship and is willing to work with you. That’s the key to success.

– Billy Muma,

Engineering Manager at 3D-P

Products & Services Used

- Fusion 360 Manage

- Consulting

- Implementation and Training

- Support