Success Stories

Porcupine Engineering Services Inc.

Porcupine Engineering is a professional services firm providing clients with a comprehensive range of services including multi-discipline engineering (conceptual and detailed design), project management, planning & scheduling, feasibility studies, cost estimates, procurement, shop inspection & field services, construction management, commissioning and start-up, and production & maintenance support.

With offices in Timmins and Sudbury, Ontario their team is composed of professional engineers, project managers, technologists, technicians, coordinators and support staff.

Project Profile

Challenge

Porcupine Engineering is committed to providing their clients with the highest quality and up-to-date field services and support.

Porcupine Engineering turned to SolidCAD in need of a full-service package that would integrate all software solutions they invested in as well as provide customized training and on-going support for all its staff members. Their goal was to incorporate an improved design strategy that would ensure value and efficiency to their clients and their projects.

The firm began with the purchase of Autodesk software solutions, such as: AutoCAD Plant 3D, AutoCAD P&ID, Revit Structure and Inventor. Prior to their switch, they realized an increase in the use of 3D modeling and client expectation to have projects delivered as a 3D model.

Originally, Porcupine Engineering produced many of their designs as a 2D model, which would often be misinterpreted by their clients— often causing rework, overall effecting the efficiency of their services.

Solution

In order to reduce mistakes and eliminate rework, implementing a comprehensive range of services that are both cutting edge and up-to-date with the changes that are happening within the industry become a priority.

SolidCAD initially provided a presentation and discussion to uncover the existing workflow, than create and deliver a complete customized training package that would include all their technological investment in; AutoCAD Plant 3D, AutoCAD P&ID, Revit Structure and Inventor.

Initially, the firm began with training for both AutoCAD Plant 3D and P&ID, but after successful preparation with the software and staff, Porcupine Engineering sought out SolidCAD to expand their customized training and include both Autodesk Revit Structure and Inventor into their existing workflow.

After the execution of this full customized training program, implementation and on-going support, Porcupine Engineering and their clients had better understanding of the design and project when rendered as a 3D model than previously as a 2D design. The firm realized that by transitioning their projects into 3D models, and creating comprehensive workflow that included a wide-range of Autodesk Software— ultimately reducing errors and rework that would often happen during the design process.

Results

- They provide comprehensive services and solutions to their clients with less people, because their staff was now trained in wide-ranging understanding of multiple software solutions.

- There has been a significant decrease in errors because 3D modeling has eliminated the revision process— helping designs get approved faster by clients.

- It has reduced the time spent on rework to correct previous errors of designs and projects, and ultimately increase efficiency.

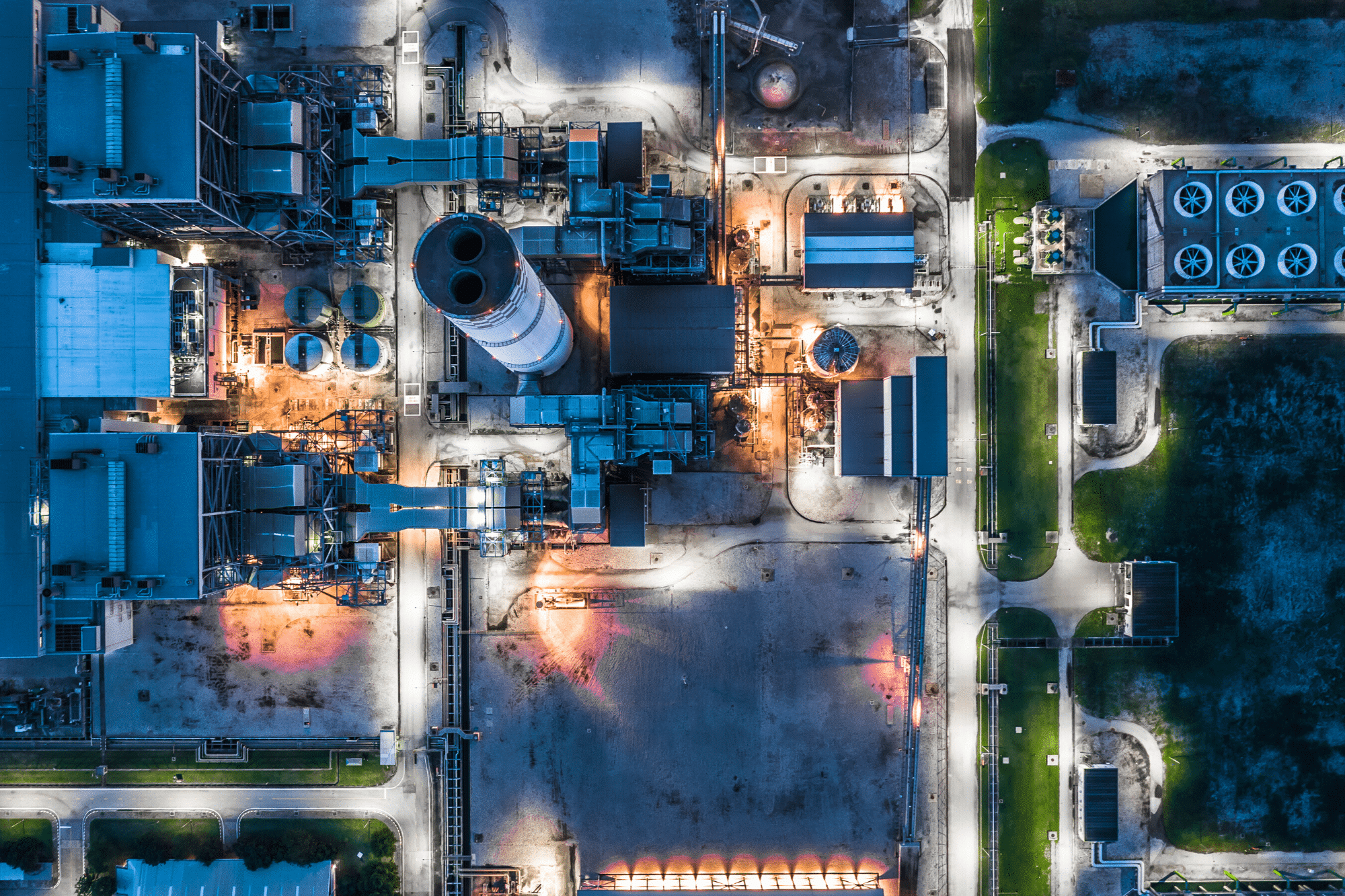

Gold New Strip Circuit

After SolidCAD’s customized training, Porcupine Engineering Services Inc, are able to provide their clients with all-inclusive services, better serving their client’s needs! Down below is an example of one of their projects for the northern Ontario’s gold producer.

Project Description

A northern Ontario gold producer was investigating the possibility of installing a new larger strip circuit for their mill.

Firms Mandate

Porcupine Engineering Services (PES) provided a Feasibility Study covering the technical and capital cost estimate considerations of the new strip circuit installation. The key components of the study were:

- Flowsheets

- P&ID’s.

- General Arrangements of the new installation c/w 3-D model.

- Single Line Diagram.

- Control Topology.

- Specification and selection of mechanical equipment.

- Capital Cost Estimate (+/- 20%).

Products & Services Used

- Customized training for AutoCAD P&ID, Plant 3D, Inventor and Autodesk Revit Structure

- Integrated the use of Plant 3D, P&ID and Revit into their existing unified workflow

- SolidASSIST: On-going tech support during the transition and integration of software