Software & Technology

FuildFlow

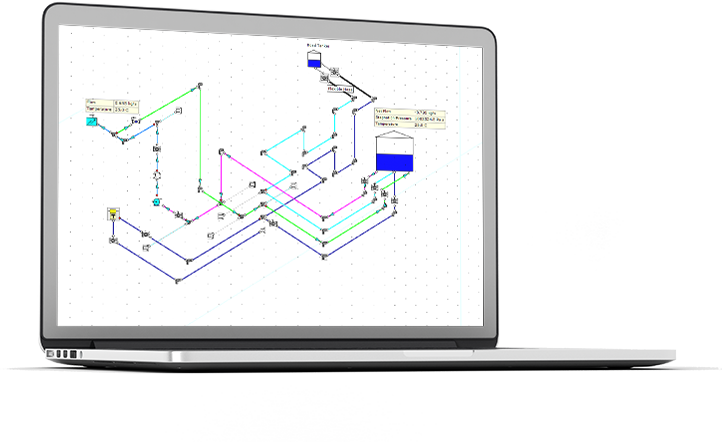

FluidFlow the Complete Pipe Flow Simulation Software

Overview

FluidFlow provides a complete solution for the design, analysis and troubleshooting of flow through piping systems for liquids, gases, two-phase fluids, settling and non-settling slurries.

This software is used by thousands of engineers worldwide from small design projects to large complex pipe networks. The efficient and accurate modeling of your pipe flow networks is essential for the design of energy efficient, safe, reliable flow systems that are easy to operate and maintain. FluidFlow can be used by mining companies, power generation plants, water treatment systems, oil/gas companies, heating and chilling systems, gas collection systems.

Key Features

Ease of Use

FluidFlow’s intuitive user interface and rapid model construction can save you up to 80% of the time you’d spend with spreadsheets. With comprehensive databases of fluids, pipes, and fittings included as standard, you can quickly and easily add your own components to the master databases. The modular environment allows you to simulate various flow types, including liquid, gas, slurry, and two-phase flow, with ease.

Calculation Accuracy

Engineers can rely on FluidFlow for proven calculation accuracy, helping you create precise designs and avoid costly mistakes. Designed and quality assured to produce economically viable and technically sound models swiftly, FluidFlow undergoes rigorous testing and verification against published data and real-world systems to ensure reliability.

Auto Sizing Technology

FluidFlow revolutionizes the design process with its fast and effective auto-sizing technology. It proposes the most economical pipe sizes based on physical properties, capital equipment costs, and energy expenses, helping you avoid over-sizing and saving both design time and capital costs.

Thermal Energy Transfer

Each FluidFlow module comes equipped with heat transfer functionality and a database of insulation materials as standard. This feature allows you to consider conduction, radiation, and convection losses, optimizing your energy usage. You can model various equipment, including shell and tube exchangers, plate exchangers, coils, and autoclaves.

Customizable Reports

Communicate your designs swiftly and effectively with FluidFlow’s fully customizable reports. Personalize reports with your company’s logo and preferred formats. You can export complete flowsheets, bills of materials, and generate reports in PDF, Word, and Excel formats.

PCF File Import

Maximize your efficiency by importing Piping Component Files (.pcf) from various CAD tools like SmartPlant 3D, CADWorx, SolidWorks, Autodesk Inventor, Plant4D, Autoplant, and Smart 3D into FluidFlow. This feature streamlines your design process and significantly reduces the time required to solve and build piping systems.

Empowering Precision and Efficiency:

Unleash the Full Potential of FluidFlow’s Comprehensive Tools and Features

Fluidflow products come with a set of powerful tools and features to reduce extensive data entry and increase accuracy. These include:

Comprehensive Fluid and Equipment Databases

Includes comprehensive databases of over 1200 fluids and 800 equipment components for pipe materials, insulation materials, and soil types, facilitating rapid model development and accurate system performance evaluations.

Automatic Equipment Sizing Technology

Proposes the most economical pipe size based on physical properties, capital costs, and energy costs. It can automatically size relief valves, bursting disks, pumps, and pipes to meet ISO and API standards.

Heat Transfer Functionality

Proposes the most economical pipe size based on physical properties, capital costs, and energy costs. It can automatically size relief valves, bursting disks, pumps, and pipes to meet ISO and API standards.

Dynamic Analysis

Uses scripting to perform time-dependent simulations, enabling investigation into system control philosophies, valve performance, and pump optimization.

FluidFlow Products

Liquids, Incompressible Flow

FluidFlow’s software for incompressible liquid flow provides a robust solution for engineers and designers working with various fluid systems. It delivers fast and accurate designs for Newtonian fluids, determines system operating pressures and flow distribution, and allows for the modeling of a wide range of line equipment items. Users can choose from three pipe pressure loss models as follows: 1) Moody (Darcy-Weisbach), 2) Hazen Williams or 3) Fixed Friction Factor (Darcy).

From Design to Communication: Seamlessly Model, Analyze, Size, and Report with FluidFlow’s Versatile Applications

Design: Utilize a comprehensive system modeling approach, incorporating the effects of connected pipes and fittings to enable both steady-state and dynamic simulations.

Analyze: Evaluate pump performance, identify energy-saving opportunities, and determine system operating pressures and flow distribution.

Size: Accurately size pipes, pumps, control valves, and safety relief devices to avoid over-sizing and optimize system performance.

Communicate: Generate fully customizable reports and flowsheets to effectively communicate design results and facilitate peer reviews and client feedback while creating a clear and transparent design audit trail.

Gas, Compressible Flow

FluidFlow’s gas compressible flow module is designed to handle the complexities of gas piping systems, where variables like pressure, temperature, density, and velocity constantly change. The software uses detailed calculations to provide accurate solutions without simplifying assumptions. Available equations of state include: Benedict-Webb-Rubin, Peng-Robinson, Lee Kesler.

From Design to Communication: Seamlessly Model, Analyze, Size, and Report with FluidFlow’s Versatile Applications

Design: Solve complex gas/vapor flow systems, ensuring accurate designs for both low and high velocity flows and considering the Joule-Thomson effect.

Analyze: Employ specific gas calculation procedures, account for changes in physical properties throughout the piping network, and automatically detect choked flow conditions.

Size: Model gas regulators, size safety relief valves to API and ISO standards, and consider various pipe and duct geometries.

Communicate: Generate fully customizable reports and flowsheets to effectively communicate design results and facilitate peer reviews and client feedback while creating a clear and transparent design audit trail.

Slurry & non-Newtonian Flow

FluidFlow’s slurry and non-Newtonian flow module is designed to handle complex fluids such as slurries, pastes, and concentrated solid suspensions, commonly encountered in industries like mining, food processing, and pharmaceuticals. The Slurry Module can be used to model settling or non-settling non-Newtonian fluids as well as Pulp & Paper Stock Flow Systems.

From Design to Communication: Seamlessly Model, Analyze, Size, and Report with FluidFlow’s Versatile Applications.

Design: Create robust slurry pipelines by modeling heterogeneous settling slurries, non-Newtonian slurries, and complex slurry flows. The module supports the calculation of system pressure losses using multiple methods and considers solids derating for pumps, ensuring optimal design for mining, pulp, and paper systems.

Analyze: Study pipeline velocities relative to deposition velocity to prevent particle settling and pipe blockage. The software helps determine slurry physical properties throughout the system and identifies operational issues, allowing for effective solutions and highlighting potential problem areas such as saltation.

Size: Utilize the rapid pump sizing function to ensure efficient and reliable pump operation. The module enables precise determination of pipe sizes and the development of Hydraulic and Energy Grade Line (EGL/HGL) plots, aiding in the evaluation of pump performance in long-distance distribution lines.

Communicate: Generate fully customizable reports and flowsheets to effectively communicate design results and facilitate peer reviews and client feedback while creating a clear and transparent design audit trail.

Two-phase Flow

FluidFlow’s two-phase flow module accurately models liquid-gas systems by tracking fluid phase states, performing flash and liquid holdup calculations, and generating flow regime maps for each pipe segment. It includes multiple two-phase pressure loss correlations and supports dynamic analysis to optimize pump performance and analyze scale build-up. Calculation methods available include Lockhart-Martinelli, Friedel, Muller Steinberg and Heck, Drift Flux, Beggs Brill or Chisholm Baroczy.

From Design to Communication: Seamlessly Model, Analyze, Size, and Report with FluidFlow’s Versatile Applications

Design: Automatically track fluid phase-state, perform flash and liquid holdup calculations, and develop flow regime maps for each pipe segment to ensure accurate modeling.

Analyze: Identify potentially unstable operating conditions, ensure safe designs, and monitor steam system quality throughout the piping network.

Size: Accurately size safety pressure relief valves, consider flow patterns and superficial velocity, and avoid incorrect equipment sizing in two-phase flow systems.

Communicate: Generate fully customizable reports and flowsheets to effectively communicate design results and facilitate peer reviews and client feedback while creating a clear and transparent design audit trail.

Get Started Today!

At SolidCAD, we believe in transforming industries with innovative solutions, and our partnership with FluidFlow exemplifies our commitment to excellence. With FluidFlow, we offer unparalleled expertise and support to businesses aiming to revolutionize fluid flow analysis and management. Together, we empower our clients to enhance their operational efficiency, reduce costs, and achieve superior performance in fluid systems.

Unlock the full potential of FluidFlow’s cutting-edge technology through our integration services. Contact us now to learn more and propel your business into a new era of fluid dynamics excellence.