SolidCAD consulting for CNC (Computer Numerical Control) machining is a hands-on approach to ensure your CAM (Computer-Aided Manufacturing) software works seamlessly with your CNC machine setup.

Whether you are looking to operationalize a standard CAM integration or configure a Robot Cell, SolidCAD’s years of experience in all aspects of CNC marketing, including mold manufacturing, automotive, and aerospace, position us to support your specific needs.

Benefits of SolidCAD for CNC Machining Consulting

We understand that your manufacturing setup is unique.

SolidCAD’s custom CNC consulting service takes the time to understand the machines that you have so that we configure the right CAM post processors and test using accurate machine tool simulation and OMV implementation.

Consulting Services

Custom CAM Post Processors

SolidCAD offers a custom CAM Post Processing consulting service that understands the demands of your unique CNC machinery, control systems, and operational workflow.

We can provide a custom service that directly imports your CAD models into your CNC systems, eliminating the need for manual programming of the CNC machines. This reduces errors and saves significant time in the manufacturing process.

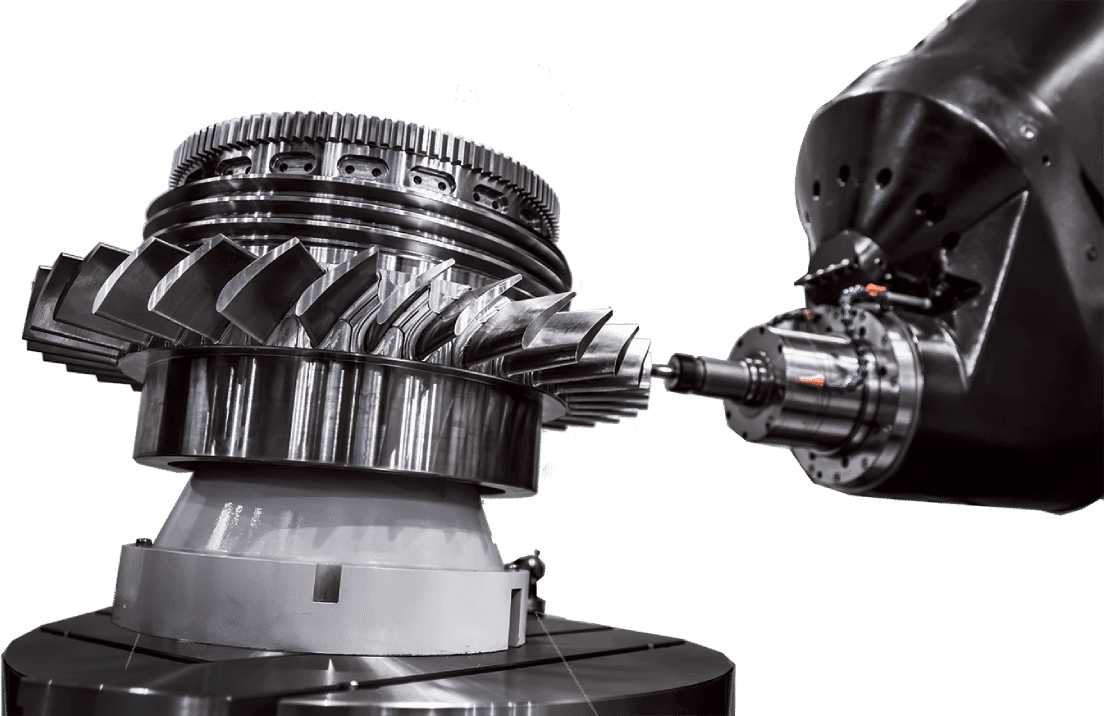

CNC Robot Cell Set-up

If you’re looking for CNC robot cell customization, then SolidCAD can help. A custom CAD integration setup for robotics and CNC machining brings together the best of design and manufacturing, leading to a highly efficient, precise, and flexible production environment. SolidCAD brings in-depth knowledge of robot cell services, from robotic grippers to complex mobile robots and high-precision inspection systems. We will ensure that each aspect of the robotic system, from payload capacities to end-of-arm tooling, is selected and integrated to meet the exact requirements of your machining operations.

Machine Tool Simulation

Machine tool simulation is a critical component to ensuring your CAM Software investment works efficiently, identifying and rectifying potential issues like collisions, tool breakage, or inefficient toolpaths, and optimizing the process for speed and waste reduction.

Our custom CNC simulations are designed to mirror the exact specifications and configurations of your CNC machinery and tools. This ensures that the simulation takes into account the unique characteristics of your setup, such as specific tool geometries, machine kinematics, and control systems, leading to more accurate and relevant simulation results than out-of-box solutions.

Shop Floor Job Tracking

SolidCAD provides a custom shop floor job tracking service unique to your setup. Shop floor job tracking in a machining environment is essential for monitoring and managing the progress of manufacturing jobs. This process involves real-time monitoring of CNC machines, tracking job statuses, and ensuring efficient workflow.

SolidCAD can also provide Product Lifecycle Management (PLM) and Enterprise Resource Planning (ERP) systems integrations, enabling a fully digital workflow from design to production planning and inventory management.

OMV Implementation

On-machine verification or OMV is a critical aspect of CNC machining as it catches potential issues early in the machining process, reducing the likelihood of producing defective parts. This, in turn, minimizes scrap and the need for costly rework.

With any CNC software solution, OMV implementation will almost always be included. And for complex setups, you can rely on SolidCAD for your OMV and CNC consulting.

Advanced CNC Machining Solutions for Complex Manufacturing

CNC automation capabilities with CAM software involve a seamless integration that streamlines the process from design to manufacturing.

SolidCAD’s advanced system designs incorporate real-time feedback and adaptive machining capabilities, so your CNC machine can adjust its operations based on sensor feedback to compensate for material variances, tool wear, or any unforeseen anomalies, ensuring the final product remains true to the CAD model.

CNC Automation

SolidCAD specializes in CNC automation where high precision is crucial for industries where tight tolerances are required.

SolidCAD’s CNC automation capabilities include standard features like full 5-axis programming, an essential feature in CNC mill systems for complex shapes and geometries, and automatic collision avoidance for toolpath optimization and collision prevention.

Advanced CAD/CAM automation software can also generate optimal toolpaths based on the geometry of the CAD model, the selected material, and the type of CNC machine. This ensures efficient material removal and high-quality surface finishes.

Trust SolidCAD Today

Experience innovation like never before. Our custom CAM software integration can optimize material usage by nesting parts efficiently and predicting the exact amount of material needed, reducing waste and costs.

SolidCAD can level up your manufacturing setup, offering improved efficiency, accuracy, and flexibility across various industries and applications.