Software & Technology

Fusion Operations

Insights for manufacturing and fabrication

Overview

Fusion Operations is production management and production floor tracking software. Schedule and manage teams, machines, and materials; get real-time production visibility powered by devices on the shop floor; track and analyze your entire production flow; track maintenance operations; easily plan future actions with fully integrated maintenance management; and leverage the real-time dashboard and connected manufacturing for better business decisions.

Access your data from any device.

- Stay connected to workers and colleagues in real-time.

- Customize alerts for real-time responses.

- Immediate alerts when machines are down or require maintenance.

Visualize workflows

- Identify bottlenecks.

- Set priorities and avoid overload.

- Increase productivity and seamless workflow.

- Continuously improve the production system.

Maximize productivity and performance

- Track each worker’s performance, in real-time.

- Monitor productivity and tasks of team members.

- Specify team resourcing: who does what, where, when, and how.

- Align shift management with shop floor activity.

Key features of Fusion Operations

Manage your company like never before

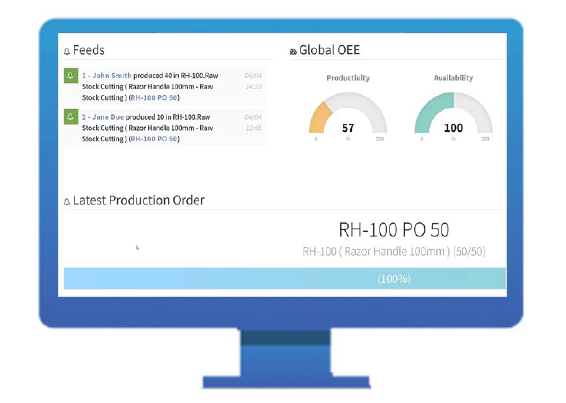

Real-time dashboards

Easily organize moving parts with real-time data for connected manufacturing.

Scheduling and inventory management

Effectively conduct MRP (material requirements planning) schedule and inventory management.

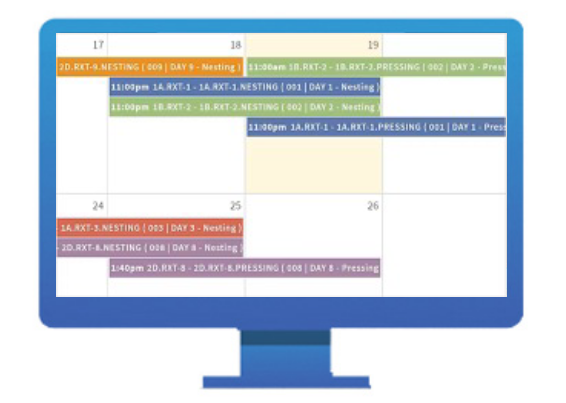

Visual workflows

Seamlessly track performance and stay organized with intuitive workflow view.

Machine and quality management

Get ahead of the curve and minimize shop floor downtime with fully integrated maintenance management.