The way we construct buildings in the United States hasn’t changed much in decades. But with the confluence of high materials prices, a skilled labor shortage, high mortgage rates and sustainability challenges, the construction industry has a need for change.

In short, there’s “an importance of trying to figure out new ways of doing things,” said Joe Benvenuto, chief operating officer for contractor LIFTbuild. The Southfield, Michigan-based company is finding success with an unconventional construction process: building from the top down, with a patented method that LIFTbuild refers to as “vertical manufacturing.”

Elevated idea

To be sure, top-down construction—where the top floor is built first and the process works its way down—isn’t totally new. Architect David Termohlen is credited with having invented the concept and further developing it in the 1970s with Charles H. Thornton, founder of Thornton Tomasetti structural engineering firm. A few buildings such as the Russian Diplomatic Compound in Riverdale, New York City, were built in the early 1970s. But then the idea—and the patent—languished, with some exceptions.

In 2017, Detroit-based Barton Malow, a now-100-year-old construction company, made an investment in the top-down approach to construction, “which fueled the effort to innovate the concept of building a building starting at the top and working downward,” Benvenuto said.

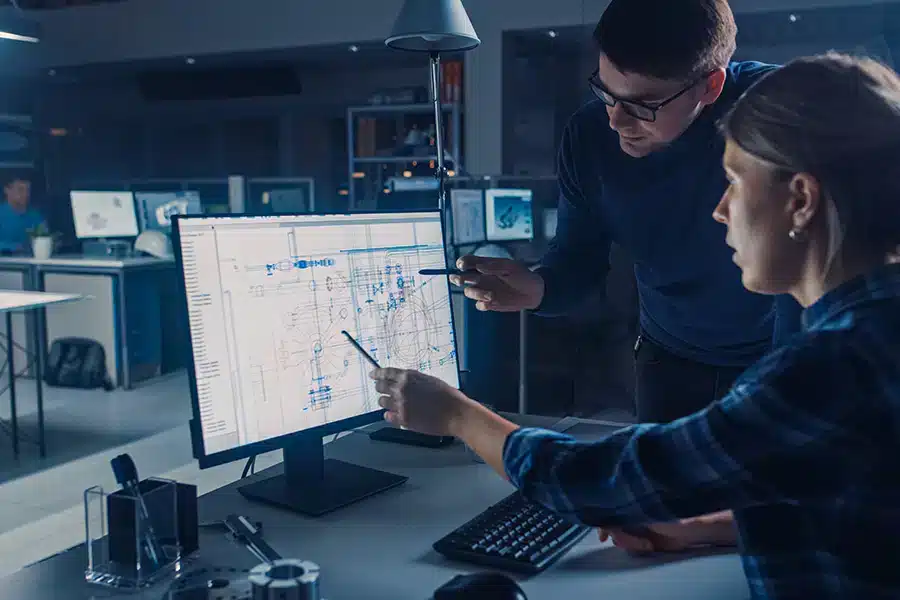

The company established LIFTbuild to meet its goal of doubling construction efficiency, and it spent about three years in research and development to improve the concept, the way the building is designed and constructed, the way the floor plates are connected and the way they’re lifted.

“In some cases, we sent the engineering methods through destructive testing to validate the process. What LIFTbuild is trying to do elevates the process to create a safer and less expensive way to build commercial buildings,” Benvenuto said. “These R&D efforts have resulted in more than 15 US patents, which protect LIFTbuild’s unique technological and delivery means and methods.”

Benvenuto added, “by 2020, LIFTbuild had significantly improved system safety with innovative means, methods and technologies centered on the superstructure, façade, assembly pad and lifting. Improved safety, increased efficiency and higher quality all lead to a better and more sustainable product for our end user.”

The Exchange

Built on a small, tight, triangular site surrounded by streets, businesses and the elevated light rail system known as People Mover, the 16-story high-rise called the Exchange in Detroit is LIFTbuild’s first proof of concept. It comprises 153 residential rental units, 12 condominiums, ground-level office space and approximately 6,000 square feet of commercial space.

The structural steel and concrete building took extensive planning, with much of the engineering done in a 3D model and a virtual environment. LIFTbuild then created a kind of manufacturing environment on the site. “Picture more of an assembly line in which a vehicle gets created. It’s very rapid. All the critical parts and pieces come into the process at just the right time,” Benvenuto said.

The build works this way:

Builders start on site by completing the foundation and underground work consistent with a conventional building. They then begin erecting concrete and steel “spines.” The spines are structural elements and could include stairwells, bathrooms, kitchens—anything, really, depending on the design, according to Benvenuto.

Next, they begin placing the concrete assembly pad, what LIFTbuild refers to as the factory floor. The assembly pad is located exactly where the building footprint is. A building’s design and geometry determine the number of spines needed. The Exchange has two, each of which encase elevators, stairs, storage and mechanical rooms.

Strand jacks, linear winches that pull heavy loads from above, are staged at the top of the spines. The floor plates are then built around the spines, about three feet off the ground with metal decking and concrete. The jacks lift the floor plates just above the builders’ heads to install the underdeck mechanicals—no need for scaffolding or ladders.

The façade and rough mechanical, electrical and plumbing go in before the floor plate is lifted. After the floor is locked into place, interior fit out begins, which includes interior walls and ceilings. Once the façade and fire protection are installed, the floor plate is lifted by the strand jack into place. Each floor in the Exchange weighs about 1 million pounds, and during placement rose about 30 feet an hour. The highest lift on the Exchange was about 200 feet.

“Placement is a cantilevered approach where we structurally connect that floor plate to the spine,” Benvenuto said. “From there the floor plate is able to provide structural stability out all the way to the exterior of the building without columns.” Every floor plate is individually supported.

Lift and learn

The foremost reason to use this method is safety, Benvenuto said. According to the Bureau of Labor Statistics, in 2022 the construction industry accounted for 1,092 deaths by falling, slipping or tripping—47.4% of all workplace fatal falls, slips and trips. “We eliminate the hazards when we install the façade at ground level. Fall protection is naturally built into it,” Benvenuto said.

Benvenuto cites increased productivity as the next major benefit, pointing to the difficulty of finding available, qualified tradespeople, rising construction costs and material pricing. “Projects have a hard time meeting financial feasibility at times,” he said. With LIFTbuild, because assemblies are done on site, often using prefabricated products and with little need for large cranes, there are fewer people needed for a build.

The method also saves time. Although builders could customize individual floors, each floor is basically a repeat of the one above. There’s more of a manufacturing process—which also can instill better quality, said Mark Tamaro, managing director of Thornton Tomasetti, who consulted on the Exchange.

Tamaro also points out that these projects can be more sustainable. Because the floor system uses steel frames, it requires less material than concrete construction. “There’s a significantly lower amount of embodied carbon than in a typical concrete product,” he said. Additionally, Tamaro said that as they learn more, there may be ways to incorporate mass timber or other materials.

Ultimately, LIFTbuild can be less expensive when compared to conventional building. Benvenuto said that using LIFTbuild, the company aims to provide savings of 10% to 20% on cost and 20% to 30% in schedule savings.

Nothing is without its challenges, however. There’s a certain level of education—for municipalities, lenders, insurance companies, builders and tradespeople—that must happen. Benvenuto said the company went through some “pretty intensive education sessions to make sure they truly understand what’s happening and address any concerns or what they would perceive as a risk.”

Tradespeople and others working onsite had safety training and “education around optimizing their time on site to make sure they were the most productive,” Benvenuto said. “But realistically, the work conditions are better and easier than you would see on a conventional project,” he added.

The education piece helped with permit applications and inspections. “Some of the preliminary inspections can happen at grade level, so it’s advantageous for them,” Benvenuto said.

LIFTbuild also collaborated closely with MIOSHA to adhere to all safety standards. The strand jack system is safe, able to take four to five times the amount of capacity needed to lift the floor plates.

Not just a novelty

Top-down construction can work beyond commercial building. There’s need for more housing, and the LIFTbuild method is “well-suited for residential construction,” Tamaro said. The method could be a game changer for the industry.

“This is something that can truly transform the way we build buildings,” Benvenuto said. “About 10 years ago, Barton Malow set the goal of doubling our efficiency by our 100th anniversary [in 2024]. The investment into LIFTbuild is a significant effort to accomplish that.”

While the Exchange is LIFTbuild’s first completed building, Benvenuto said they have a handful of opportunities coming. “With the Exchange, we’ve been able to validate the technology. Now our focus is to commercialize LIFTbuild on a broader scale throughout North America.”

Top-down in action: A different take

In 2014, Thornton Tomasetti used the “traditional” top-down build method to build the Marriott Marquis in Washington, D.C., said Tamaro, who was the project’s engineer of record. “We constructed the building both upward from the ground level and downward simultaneously.”

Builders drill into the site and install shafts, called piers or plunge columns, Tamaro said. In the case of the Marriott these were dug down about 130 feet to get below the lowest basement level. The piers stop at the floor level of the first floor. The build continues upward in the traditional way with concrete columns.

At the same time workers are building up, others are excavating below, around the piers. “If you do it right, you can top out the building before you get to the bottom of the basement,” Tamaro said.

Why do it this way? “In the case of the Marriott job, there were two fundamental reasons,” Tamaro said. “One is speed of construction.” In a conventional build you’d dig all the way to the bottom and then come back out. With this top-down method, you effectively start in the middle and work down and up at the same time. There’s no wait time.

The other reason to choose this method is that this particular site was constrained with both a high water table and the need to go extremely deep as there were multiple basement levels. “This method of construction allowed us to build deeper and avoid having to address the groundwater,” Tamaro said. “Doing things this way made an otherwise very challenging project feasible.”