Overview

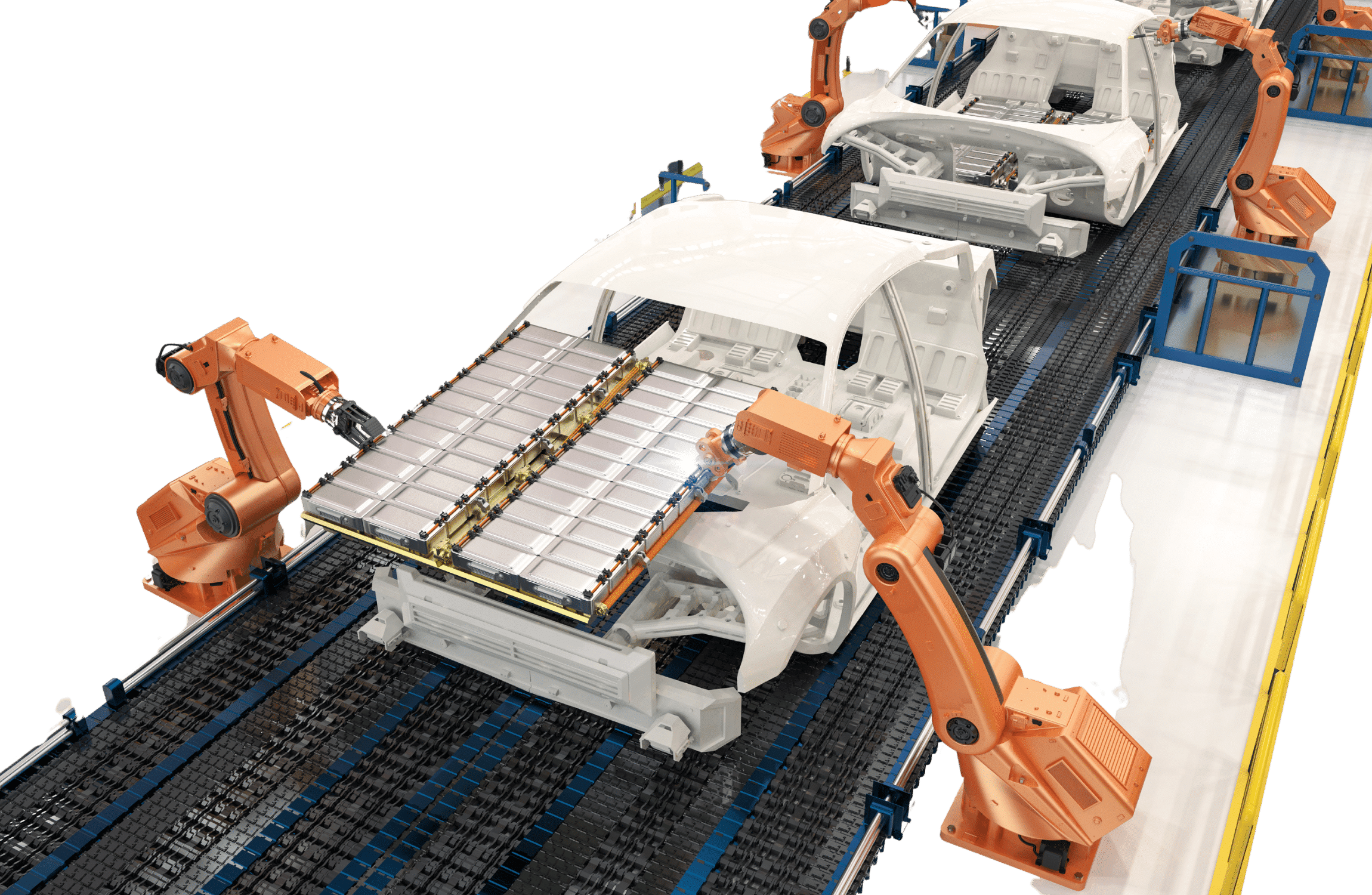

The manufacturing industry is seeing a huge impact on the automation of the assembly line and is undergoing a transformative evolution, embracing trends that redefine the landscape. There are four major trends taking center stage: innovative robotics redefining efficiency, IoT integration creating smarter factories, and AI that is redefining the manufacturing process of production, predictive maintenance and quality control.

With advancements of robotics, at the forefront, there has been a steady increase in efficiency with intelligent machines that are seamlessly integrating into workflows, fostering precision and speed. While simultaneously, the integration of the Internet of Things (IoT) is ushering in an era of smarter factories, where real-time data analytics and predictive maintenance optimize operations and minimize downtime.

But with innovation at every corner, manufacturers have been heavily impacted by incorporating methods of the buzzing concept of today: Artificial Intelligence (AI). As an integral player, AI is altering assembly line automation through intelligent algorithms that optimize production schedules, enhance quality control, and help manufacturers adapt to dynamic demand. Machine learning algorithms can now analyze data to predict equipment failures, ensuring proactive maintenance that minimize downtime and cost.

We are seeing AI-powered collaborative technologies enhancing communication, fostering a more efficient and innovative production environment.

Transform Your Assembly Line with Cutting-edge Consulting

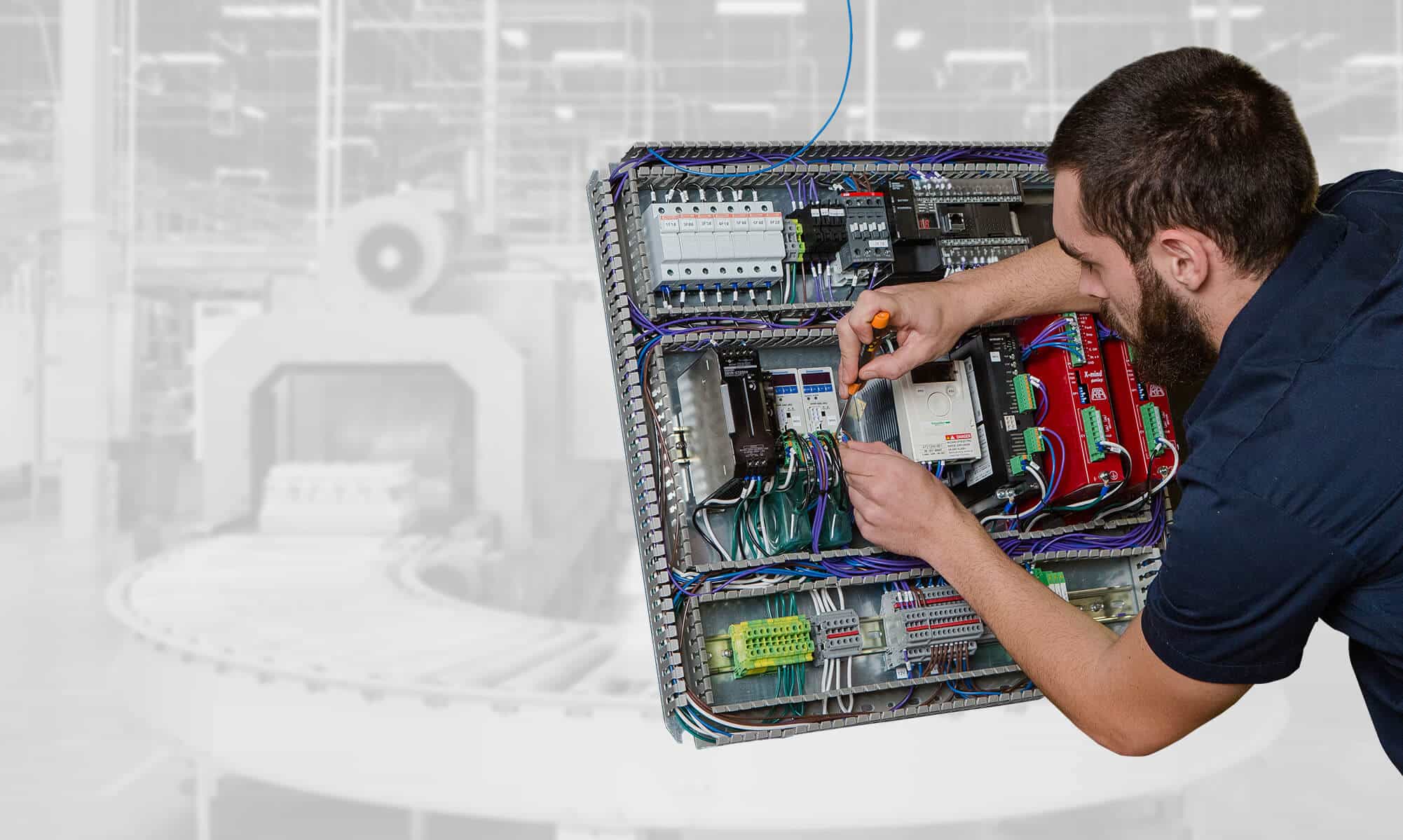

Digital transformation is vital to the advancement of automation assembly line as it reforms traditional manufacturing processes, driving efficiency, agility, and competitiveness.

Embracing digital transformation ensures that your organization is equipped to navigate future industry trends, foster innovation, and create long-term sustainability in an increasingly digital landscape.

Enhanced Efficiency and Productivity:

Digital transformation optimizes assembly line workflows, leveraging advanced technologies can help better automate tasks, reduce downtime with predictive maintenance, and fine-tune production schedules. This results in a more agile and efficient assembly line, enhancing overall operational excellence.

Cost-Efficiency and Resource Management:

Companies investing in digital transformation achieve significant cost savings by minimizing errors, reducing waste, and optimizing resource allocation. Predictive analytics and data-driven insights enable smarter decision-making, preventing equipment breakdowns and ensuring efficient resource utilization. Automation also translates to labor savings, enabling focus on higher-value tasks.

Strategic Competitive Edge:

In the dynamic manufacturing landscape, digital transformation is a strategic imperative for staying competitive. Embracing innovative technologies provides a competitive edge by accelerating product delivery, improving quality, and adapting swiftly to market changes.

Revolutionizing Assembly Line Automation with Advanced Solutions

Adopting advanced digital technologies in the Assembly Line Automation sector significantly boosts process efficiency and product quality. Solutions from Autodesk, such as Fusion 360, Inventor, Autodesk Product Design & Manufacturing Collection, Autodesk PLM & PDM, and Autodesk Vault, deliver unparalleled capabilities in design, manufacturing, and data management. Fusion 360 offers integrated CAD, CAM, and CAE to streamline the entire manufacturing process, while Inventor specializes in advanced 3D mechanical design. The Autodesk Product Design & Manufacturing Collection provides a robust suite of tools for comprehensive product development and manufacturing planning. Integrating Product Lifecycle Management (PLM) further elevates these advanced solutions, ensuring seamless workflow and product lifecycle oversight. Autodesk Vault enhances collaborative data management, ensuring accuracy and efficiency.

Discover how these advanced solutions can transform your assembly line operations. For personalized guidance on implementing these technologies, please reach out. Let’s revolutionize your manufacturing processes with the latest in digital innovation.

Showcasing Our Thought Leadership Through Real-World Stories

Resources

Featured

Blogs

Additional resources

Insights to Transformation

How we can help

Investing in digital transformation is essential for organizations seeking to thrive in today's dynamic business landscape. Beyond adopting cutting-edge technologies, it's a strategic move to future-proof your operations and remain competitive. Our services go beyond efficiency gains; they reshape organizational culture, fostering agility and responsiveness to market demands.

Your investment is not just a cost; it's a means to enhance customer experiences, increase employee satisfaction, and improve your bottom line. Our promise is to be your special resource in achieving the highest growth, quality, and efficiency throughout your digital transformation journey.