This story was originally published by on the Bluebeam Blog.

COVID-19 has forced many workplaces to embrace remote working. However, for some employers, working from home and self-isolation directives could potentially devastate business viability. Developing and enabling work-from-home opportunities has come with distinct challenges, particularly as many employers are exploring this territory for the first time. While frameworks, policies and procedures can be developed through a logic-based approach, ensuring your workforce is productive and motivated can be more challenging.

The rise of remote working in the construction industry

Global consulting firm McKinsey believes hybrid working arrangements will continue beyond the COVID-19 pandemic. Australian workers have demonstrated this in their widespread exodus from capital cities.

In its paper titled “What’s next for remote work: An analysis of 2,000 tasks, 800 jobs, and nine countries,” the McKinsey Global Institute estimates that about 1 in 5 members of the Australian construction workforce could work between three and five days remotely each week.

The opportunity to work remotely depends on various factors, including the nature of particular occupations. The varied roles in the industry mean companies may need to tailor policies to suit different job functions. For example, marketers may more easily achieve a hybrid or full-time work-from-home arrangement, while tradespeople will be required on-site.

New technologies and digital connectivity are imperative to bridge the divide between team members and the functions of the business, not only to achieve tasks but as part of a broader focus on maintaining and improving motivation and productivity.

Factors that can affect employee motivation and productivity

Whether working on-site or remotely, workplace culture is central to your team’s performance, and positive organizational culture begins with leadership. The relationships between managers and their team is a significant driver of workplace satisfaction, alongside meaningful work.

“Motivation depends on balancing what is meaningful with what is manageable.” – Adam Grant.

The mismatch between what science knows and what business does – predominantly focusing on rewards and punishment in terms of workplace motivation – has been researched for decades. Consistently, research has revealed that instead of the carrot and stick approach, the building blocks of an engaged and productive workforce should focus on opportunities to embed intrinsic motivation.

While we may choose roles for professional opportunity and economic reward, our performance is driven by organizational culture and commitment to autonomy, mastery and purpose. Working with a manager who does not communicate well or offer clarity or with a team who doesn’t believe in the end goal is demoralizing and can lead to poor performance. Simple issues, such as inadequate tools or a lack of technology, also act as roadblocks to performance and motivation.

Tips for keeping remote teams motivated and productive

With today’s teams increasingly dispersed, developing and implementing ways to maintain and build motivation and productivity is more important than ever.

Our top ways to future-proof your workforce include:

1. Prioritize team collaboration and connection

Collaboration and connection begin at a leadership level. If you build this into your immediate reporting structure, the effect will cascade throughout other teams.

Embed both informal and formal collaboration into regular team meetings. To foster collaboration and participation, each team member could take turns leading weekly catch-ups.

Factor in opportunities to brainstorm challenges and lead by example. Bringing a problem to the table for the team to solve encourages lateral thinking and teamwork and demonstrates you value your team members’ contributions.

2. Build relationships with your team members

If you have a reputation for being hard to reach in the office and an arm’s-length boss, you will find it difficult to establish good relationships when managing from a distance. Good leaders understand and demonstrate good communication, including building rapport, listening, and clearly articulating goals and expectations.

Regular one-on-ones with team members, including informal chats and task-specific meetings, break down barriers and build trust and communication. The greater the level of trust, the more likely it is that your team members will be proactive in picking up the phone or sending an email when a challenging problem or potential opportunity lands on their desk. Such trust also means team members have greater confidence in using initiative and taking the lead in progressing work and adding value to their project.

Create opportunities for team members to work outside their core scope to grow their expertise and contributions. This can help support succession planning and improve staff loyalty and retention.

3. Arm your team with the tools they need to collaborate and build performance.

“Give ordinary people the right tools, and they will design and build the most extraordinary things.” – Neil Gershenfeld

There are many tools ready to be tapped into to build motivation and productivity across teams. Some will be role-specific – such as Asana for collaborating across the business and Xero for accounting. The whole organization can collectively use other generic tools – for instance, Zoom and Microsoft Office’s cloud-based 365.

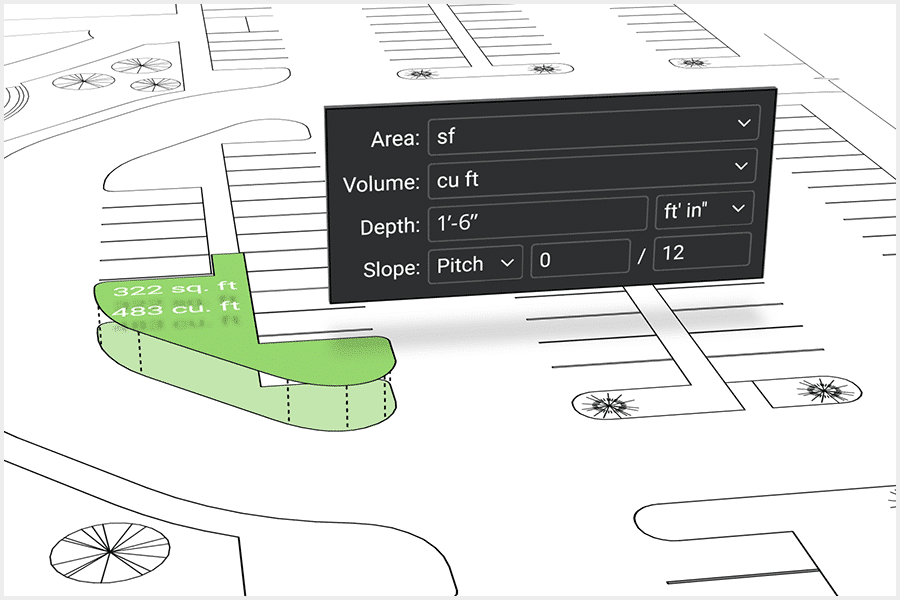

Industry-specific tools are critical for construction businesses seeking to build a diverse workforce that supports remote team members. This includes tools such as Revu that enhance sharing information in real-time, keeping teams on the same page through the design process.

4. Recognize and celebrate success

Most team members contribute their expertise as part of a much bigger job or project. Keeping the team in the loop of the project’s progression, completion and success helps them stay connected to the bigger picture while building a sense of belonging and achievement. Sharing outcomes and lessons learned also helps build improvements in the future.

Remote team members are valued contributors to all teams. Ensuring you find ways to connect them to the broader team and embedding in practices to motivate and engage your people will deliver better outcomes for your business as a whole.

Motivation is not a one-size-fits-all approach. And for the construction industry, it’s critical to understand the purpose of your approach and how it will enhance outcomes. This is central to your strategy to ensure your staff feels connected and valued and that your business uses tools to streamline work and improve collaboration.