- In Vancouver, Canada, window company Starline Windows was an early adopter of digital design and uses lean processes to deliver custom products.

- The 2008 recession and COVID-19 pandemic both jumpstarted the company’s digital transformation to compete in a packed marketplace.

- The result is a greener, more profitable, and more responsive business delivering more value to customers, partners, and employees.

- Starline’s ongoing digital transformation has accelerated the design-to-delivery process by connecting data from various applications.

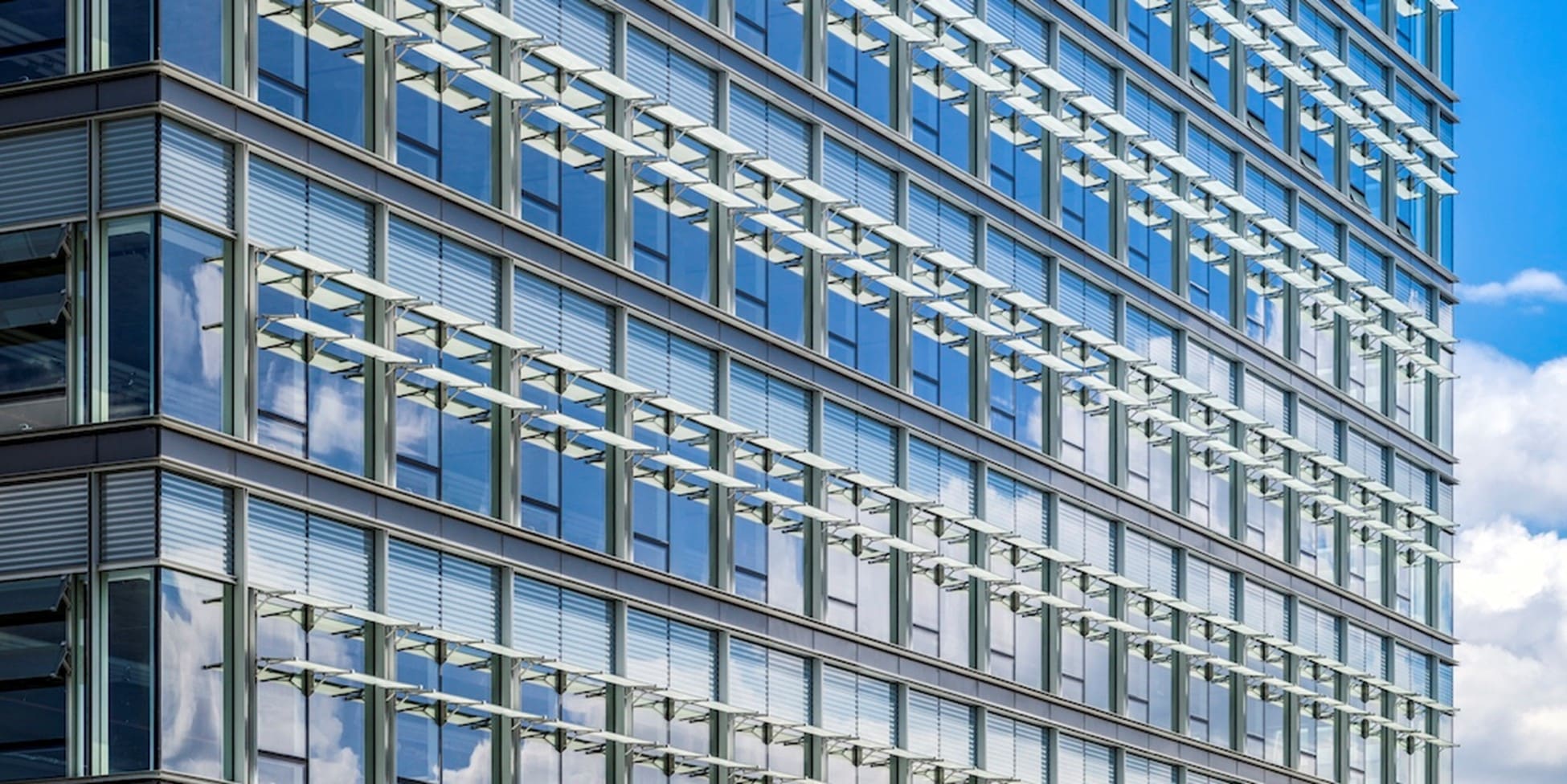

If buildings were bodies, the exterior would be the skin, blocking wind and rain while keeping everything inside warm and comfy. But in construction, vents, pipes, doors, and windows repeatedly puncture that outer layer. For a building to sustain the environment inside, those elements have to fit perfectly and seal seamlessly.

Defects that measure only millimeters become huge headaches if a window doesn’t quite meet spec. It may need to be trimmed onsite or reordered and replaced. Either way, it amounts to time lost and added expense. To get it right the first time, Vancouver, Canada–area window company Starline Windows has embraced digital design, making it the foundation for great industry relationships, profitable growth, and a more sustainable operating model. Starline has become a supplier of choice for many high-profile construction projects, collaborating effectively with internal and external partners.

Integration for Better Outcomes

Starline designs and manufactures architectural aluminum window systems for residential and commercial buildings. In business since the early 1970s, the company has delivered thousands of projects in its key California and Canadian (British Columbia and Alberta) markets. In fact, Starline Windows is responsible for making and installing the windows and doors in 25% of the high-rise buildings constructed during the past 50 years of the Vancouver, Canada, downtown core—the area most known for the city’s iconic skyline.

Starline’s array of window products includes punched, window-wall, curtain-wall, and balcony door. Unlike many manufacturing businesses that opted to outsource in the 1980s, Starline has stuck with a vertically integrated corporate structure in which most of its supply chain is company-owned, including state-of-the-art, fully automated manufacturing facilities.

“It’s a really special company,” says Catherine Walmsley, virtual construction manager at Starline. “We’re quite unique, and I think that comes down to not just what we do, but how we do it. We own our own supply chain. We do our own assembly and manufacturing. We have in-house IT support, and we do our own installation and construction.”

When Starline takes on a job, “we work with our partners to meet their needs as well as our own,” Walmsley says. However, even with the level of control afforded by its integrated structure, the company still faces business challenges common to the envelope trades, including a lack of design collaboration with architects and contractors, poor visibility for field personnel when design revisions happen, and limited data sharing between the office and the field. A lack of cross-department collaboration can also get in the way of efficient logistics.

In a highly competitive market, working closely with project stakeholders to demonstrate value can be make-or-break. In its 2022 Pulse Report, Window + Door Magazine found that 62% of contractors were on the hunt for new window suppliers to protect the supply chain and keep up with customer requirements. Issues like flexibility, turnaround time, material availability, and pricing were among the top reasons cited for shopping around.

Traditional Structure, Modern Challenges

“When you’re working on a complicated project, you need to be able to work with others,” Walmsley says. “So it’s important for us to be able to understand the process as a whole.”

Improving end-to-end process clarity benefits every architecture, engineering, construction, and manufacturing business, but rising demand for custom designs makes this goal more challenging. As requirements become more tailored and less standard, better tracking and traceability across the product lifecycle is essential.

Working with architects closely at the outset and ensuring design commitments are being met from manufacturing to installation are necessary to meet custom requirements. The COVID-19 pandemic and its increase of remote working have compelled an industrywide rethink of how tighter collaboration and greater visibility can be delivered to clients.

But just as it decided early on to stick with a traditional business structure, Starline also became a digital early adopter. That’s put the company on the right footing to meet today’s challenges.

A Digital Early Adopter

“We do everything from design to manufacturing, installation, and even shipping,” Walmsley says. “That’s a lot of territory to cover, and anything you can do to virtualize construction information is a benefit.”

Starline recognized that issue as far back as the early 1980s, when it started the shift from paper drawings to computer assisted design (CAD).

“We were pretty early to embrace CAD,” Walmsley says. “We had an amazing IT guy, and once CAD went open source around 1985, we saw the opportunity to replace paper-based workflow and reuse all the data contained in hand drawings.”

Things really changed in the aftermath of the 2008 recession, when macro considerations forced the company to find new ways to rationalize costs and downsize—without sacrificing quality or delivery.

“We were always fans of lean operating principles, but after 2008, we had to go really lean and find ways to deliver the same number of projects with fewer people,” Walmsley says. “But we also had to enable the ones who stayed to work more efficiently. Our people in the field in the buildings were very attached to their pieces of paper, but when we put an iPad in their hands, it was a huge game-changer. Suddenly we could provide change paperwork on the fly without having to call FedEx and have a ream of paper delivered to the site.”

Along with digitized field operations, the company’s manufacturing facilities are almost completely automated. “Some manual processes remain, but they are few and far between at this point,” Walmsley says. “Most of our manufacturing assembly is now roboticized.”

Starline’s ongoing digital transformation has accelerated its design-to-delivery process by connecting data from Autodesk Fusion 360, Vault, Revit, Inventor, and the Autodesk Construction Cloud. Walmsley says those tools, which integrate information from multiple systems and generate 3D designs, help complete the digital operations picture.

They’ve made it easier to deliver on bespoke design needs for major projects such as Civic Plaza in Surrey, BC. It’s the city’s tallest building and some of its guitar-pick-shaped skylight windows set the bar high for Starline’s capabilities.

“We could do circular shapes, but we had never attempted something so custom,” Walmsley says of the buildings nonstandard skylights. “They are huge—8 feet—so it was just an incredible feat to be able to put it all together and to coordinate. The lead time was extensive, and it was very challenging to get them to the building and installed on time.”

Sustainable Benefits

Doing more with less but still doing it better is digital’s core mission. Walmsley says that for Starline, it’s made business planning easier and improved quality control. “Today, I can pull data from Revit, from Inventor, from our ERP and inventory-control systems to track all of the various activities happening and give upper management the information they need. It all adds up so that we know how many windows we can produce, how close we are to reaching project commitments, and when our next sale is due.”

Going digital has also had green benefits. It’s dramatically reduced the reliance on paper, as well as the volume of toner and other printer consumables the company uses. There’s also much less physical waste for disposal because more accurate design and manufacturing means fewer deficiencies and less cutting and trimming at the building site.

When deficiencies do occur, they can be captured and tracked to avoid replicating the same mistakes.

Walmsley says the real test, however, is how well a digital tool helps Starline work more closely with clients, partners, and other stakeholders: “It’s not just about us. It has to be beneficial to the architect, to the developer, and to the customer. In the end, the biggest selling feature is knowing we’re delivering something that’s going to make the building sell, that’s going to make everyone’s life easier, and that’s going to make people want to work with us again.”