Case Study

Built to Scale: How Greenlane Reinvented Its Operations for Sustainable Expansion

An Energy Transition Leader at an Inflection Point

As a pioneer and leading specialist in biogas desulfurization and upgrading, Greenlane Renewables has been actively contributing to the decarbonization of our planet for over 35 years with more than 355 systems supplied into 28 countries. Their systems transform biogas generated from organic waste into high-value low-carbon grid-ready renewable natural gas (“RNG”) from a wide range of sources such as landfills, sugar mills, dairy farms, wastewater, and food waste. But as climate urgency accelerated and global demand surged, Greenlane faced a familiar challenge for high-growth innovators:

How do you scale complex engineering operations without compromising quality, innovation, or sustainability?

Greenlane was expanding fast, deploying biogas upgrading systems internationally. But behind the scenes, the company’s legacy Engineer-to-Order (ETO) model was slowing progress.

– Duran Cheung, Director of Engineering Services, Greenlane Renewables

The Growing Pains of a Custom Engineering Model

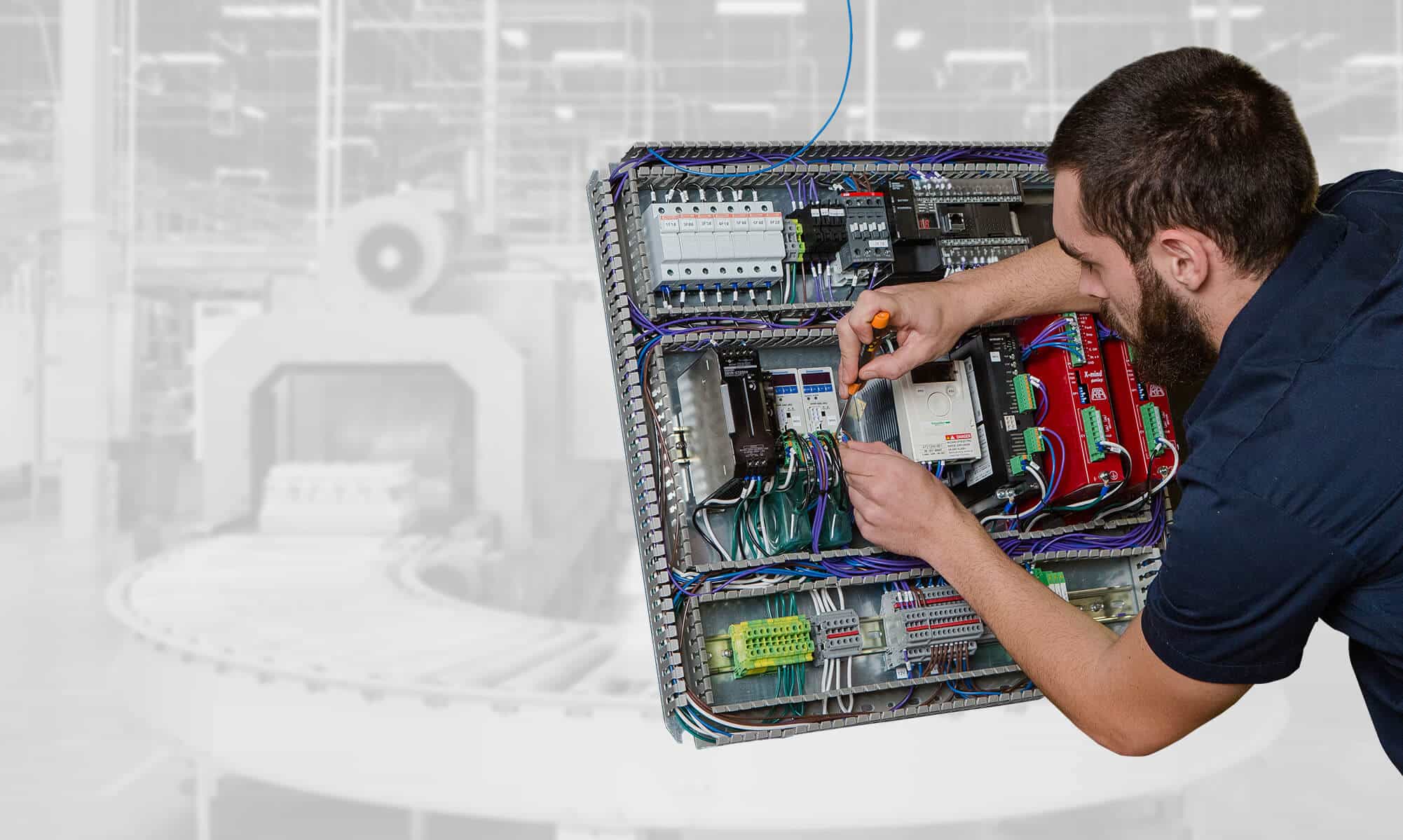

Greenlane’s engineering team had long been known for its adaptability and custom project delivery. However, the Engineer-to-Order (ETO) model led to duplicated efforts, documentation that was challenging to track, and siloed systems that made it difficult to scale.

“At one point, we had 50+ copies of the same document floating around. It wasn’t just inefficient—it made it harder to innovate. We needed a better way to manage product data and eliminate unnecessary work.”

— Duran Cheung

Key Challenges holding them Back

Behind Greenlane’s reputation for innovation was a set of growing operational challenges. Teams were working from disconnected systems, and critical information was often slow to communicate and required manual operations. Collaboration between engineering and procurement lacked structure, and reusing past work often meant starting from scratch.

There was no single place to track a part’s full lifecycle—and as the company scaled, so did the complexity of its compliance and reporting needs. Better traceability was required. The opportunities for improvement were becoming impossible to ignore.

The Shift: From Custom Chaos to Configured Clarity

Instead of hiring more engineers, Greenlane made a strategic decision: transform their business model from ETO to Configure-to-Order (CTO). This shift would require new systems, tighter workflows, and a single digital thread from design to delivery.

They partnered with SolidCAD to lead the transformation.

“We weren’t just adding software. We were rethinking how we work as an organization. SolidCAD brought the knowledge and their unique support to help us do it right.”

— Duran Cheung

The Solution: Fusion Manage + SolidCAD Expertise

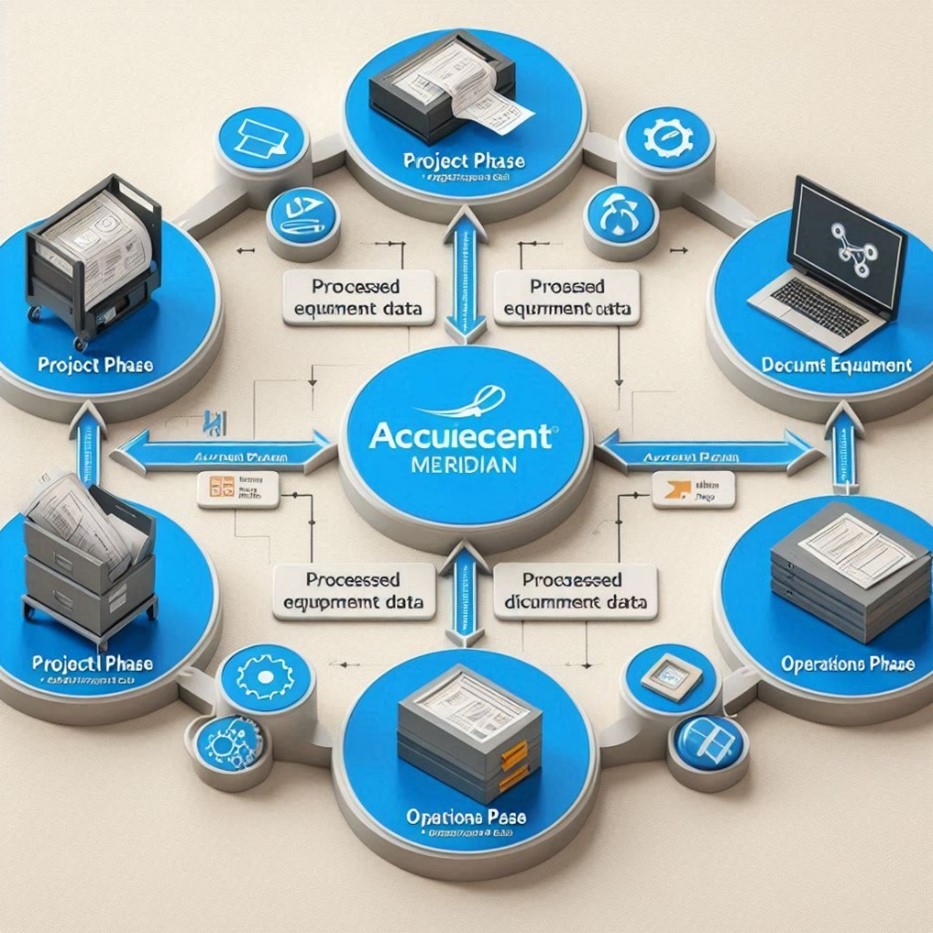

SolidCAD helped Greenlane implement Autodesk Fusion Manage, configuring the cloud-based PLM platform to meet the company’s unique needs as a cleantech solutions provider. Workspaces were created for Engineering, Supplier Management, and Quality, standardizing everything from part creation to BOM lifecycles.

To amplify impact, SolidCAD also integrated Fusion Manage with NetSuite ERP using the Nexus connector, ensuring seamless and instantaneous data handoffs from engineering to procurement.

“Now, when an item is approved in PLM, it flows into ERP automatically—with part numbers, supplier, and documentation data included. That kind of automation didn’t exist before.”

— Duran Cheung Continue reading “Built to Scale: How Greenlane Reinvented Its Operations for Sustainable Expansion”