This story was originally published by on the Bluebeam Blog.

Municipalities must adopt digital collaboration tools to streamline permitting and meet CHIPS Act demands. Here’s how they can start

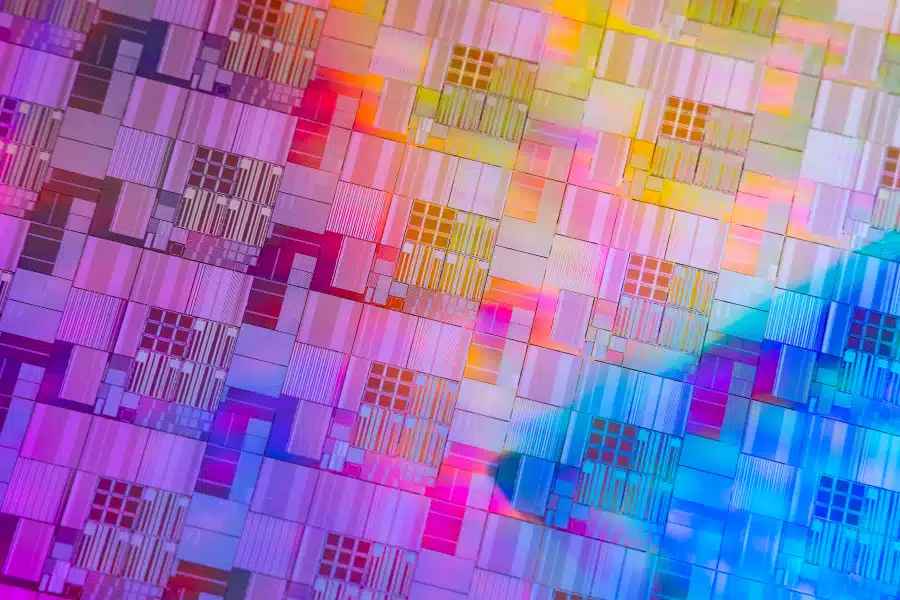

The CHIPS Act, a landmark investment to boost semiconductor manufacturing in the United States, promises to reshape the nation’s technology landscape. With more than $50 billion allocated for domestic production and billions more for research and development, the act represents a bold step toward reducing reliance on foreign chip suppliers.

Yet, while much of the focus has been on manufacturers and contractors, a critical piece of the puzzle lies with local governments.

Municipalities will play a pivotal role in the success of these projects, particularly in managing construction permitting and records. For these high-profile initiatives to succeed, local governments must embrace digital collaboration tools to streamline processes, minimize delays and align with the advanced systems used by contractors.

How Municipalities Drive Success in CHIPS Act Construction Projects

The CHIPS Act’s ambitious goals depend on efficient project management at all levels. Semiconductor plants, with their high-tech infrastructure and specialized requirements, demand a seamless permitting process to avoid costly delays. But many municipalities still rely on outdated, paper-based workflows for permitting and records management.

These inefficiencies risk creating bottlenecks that could derail timelines and escalate costs for critical projects.

Local governments are key gatekeepers in ensuring compliance with regulations while supporting contractors with the tools they need to execute efficiently. Adopting digital collaboration tools will be essential to meeting these demands.

Maximizing Efficiency with Digital Collaboration Tools for Municipalities

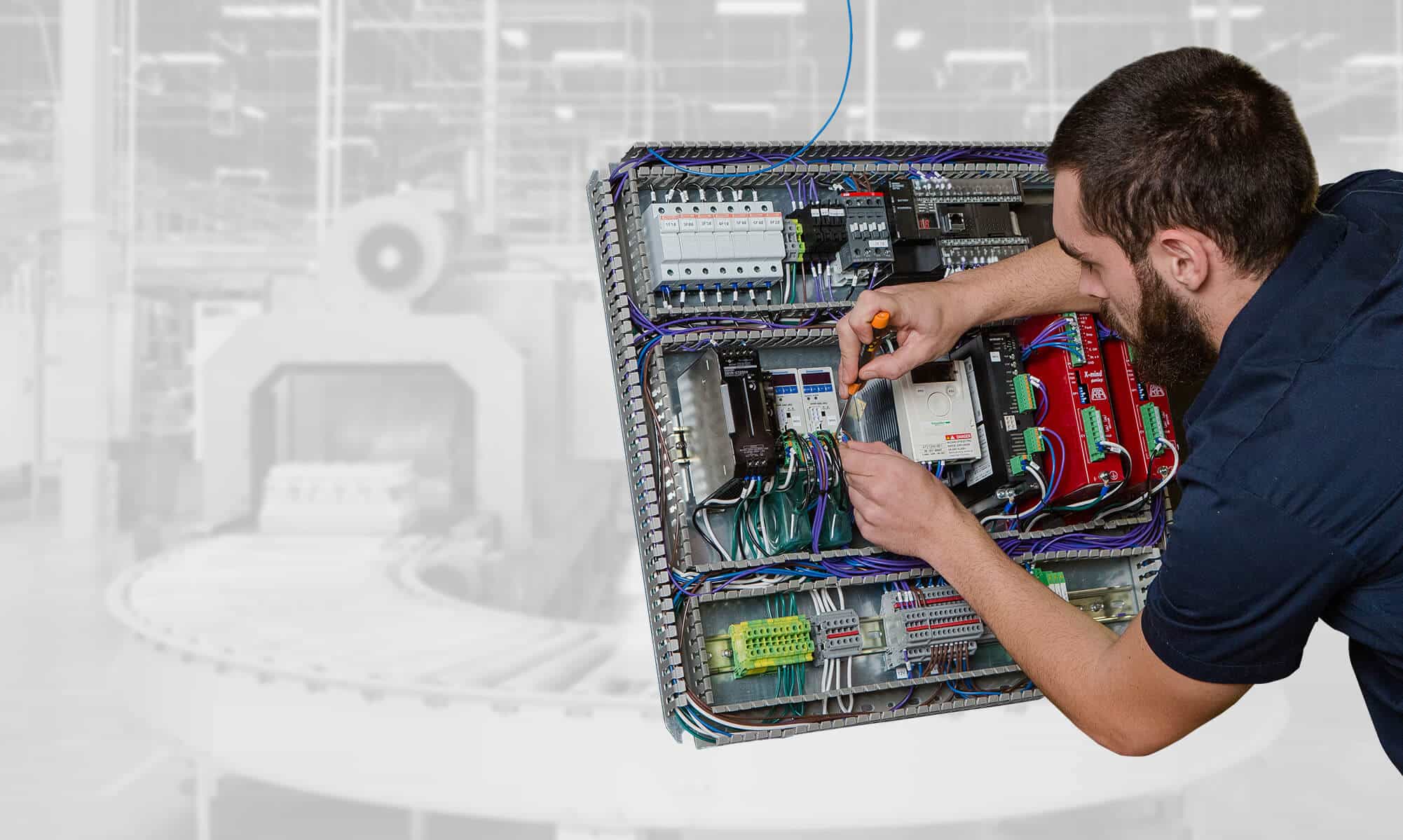

Digital collaboration tools are transforming construction workflows by offering centralized platforms for managing permits, plan reviews and records. These tools facilitate real-time communication between stakeholders, automate compliance tracking and reduce errors in documentation.

For municipalities, they offer an opportunity to modernize their systems and align with the digital practices contractors are increasingly adopting.

A 2019 study by McKinsey & Company highlights that digital tools can reduce project delays by up to 45% and improve productivity by 14% to 15% in large construction projects. Using such tools, municipalities can significantly enhance their ability to process permits, manage records and support CHIPS Act projects.

Lessons from Successful Digital Plan Review Implementation

Some municipalities have already begun transitioning to digital systems with impressive results.

The city of Seattle serves as a prime example of how digital plan review systems can revolutionize municipal permitting processes. By implementing Bluebeam, Seattle’s Department of Construction and Inspections transformed its approach to handling project submissions.

The city transitioned from cumbersome, paper-based workflows to a streamlined digital system that enabled real-time collaboration among stakeholders, improved accuracy in plan reviews and significantly reduced processing times.

Practical Strategies for Municipalities to Embrace Digital Transformation

Municipalities looking to modernize their processes can take the following steps to prepare for the demands of CHIPS Act projects:

- Assess Current Processes: Conduct a workflow audit to identify inefficiencies in permitting and records management.

- Invest in Digital Tools: Choose platforms tailored to municipal needs, such as those offering review capabilities, automated compliance tracking and document storage.

- Train Staff: Provide training for staff to ensure a smooth transition to digital tools and minimize operational disruptions.

- Collaborate with Contractors: Align workflows with contractors’ digital systems to ensure seamless communication and avoid mismatches.

- Monitor and Optimize: Establish key performance indicators (KPIs) to measure the efficiency of new processes and make continuous improvements.

Addressing Challenges in Municipal Digital Transformation

While the benefits of digital transformation are clear, municipalities may face challenges such as budget constraints, resistance to change and integration difficulties. Addressing these issues requires a proactive approach:

- Budget Constraints: Advocate for CHIPS Act funding to include allocations for local digital upgrades.

- Resistance to Change: Emphasize long-term cost savings and efficiency gains.

- Integration Challenges: Implement phased rollouts and seek vendor support for training and technical assistance.

Building a Future-Ready Vision for Modernized Municipalities

As semiconductor manufacturing becomes a cornerstone of the US economy, municipalities must rise to meet the challenge of supporting these projects efficiently.

Digital collaboration tools offer a pathway to modernize workflows, improve interdepartmental coordination and ensure compliance with complex regulations. By adopting these tools, local governments can position themselves as valuable partners in the success of the CHIPS Act.

Modernization is not just about keeping up with contractors; it is about creating a resilient, future-ready public sector capable of supporting large-scale, transformative projects.

As the CHIPS Act lays the foundation for America’s semiconductor future, municipalities can play a key role in building it—efficiently, effectively and digitally.

ion in the industry. It underpins our value and supports our future growth.”