Toronto, November 12, 2024 – SolidCAD, a leader in technology consulting and digital transformation, proudly announces its latest partnership with Liggo, a cutting-edge shopfloor monitoring and management solution, to enhance advanced manufacturing capabilities across Canada.

Liggo is renowned for its ability to connect users, systems, and machines in a seamless ecosystem, capturing critical factory know-how and optimizing production efficiency. This partnership enables SolidCAD to bring Liggo’s innovative platform to a broader market, empowering manufacturers to elevate their operations, increase productivity, and scale efficiently.

“With Liggo, manufacturers can orchestrate their shop floor and streamline operations like never before,” said Stéphane Agnard, President of Liggo. “Our solution helps businesses multiply their value by up to three times, increase productivity by 25%, and onboard employees five times faster – all proven by customer results.”

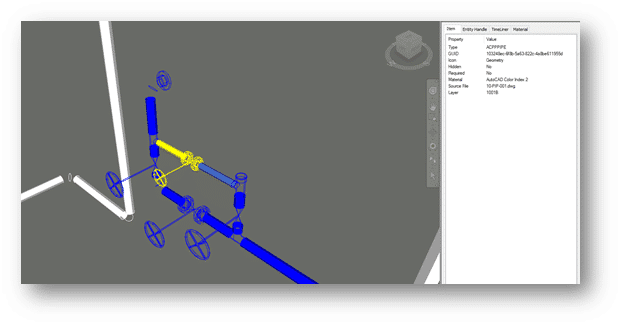

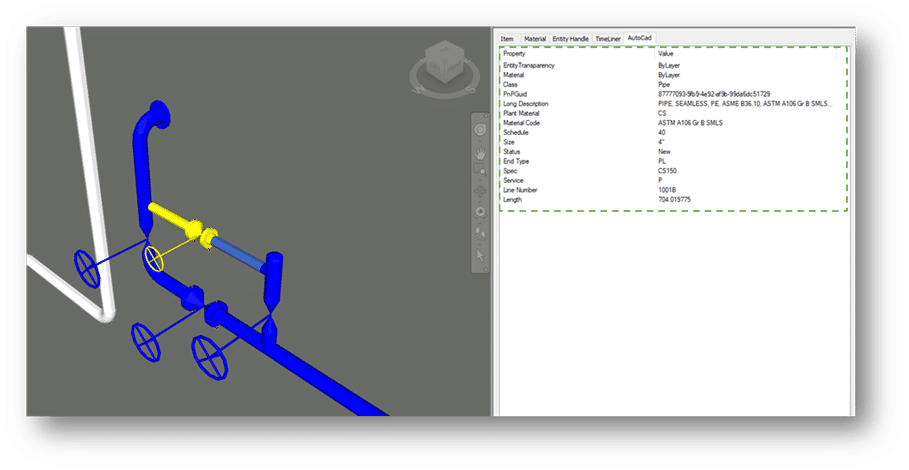

Liggo is an all-in-one platform, connecting to existing equipment and systems, including ERP solutions, and offers comprehensive features such as monitoring, scheduling, quality system control, tool database management, and up to fully automated process control. It simplifies complex workflows while democratizing expertise across the workforce, making technology more accessible to operators, engineers, managers, and executives alike.

By partnering with Liggo, SolidCAD strengthens its position as a key player in the digital transformation of the manufacturing sector. “Our goal is to help manufacturers harness the full potential of their production capabilities,” stated Marty Cornacchi, Director of Advanced Manufacturing at SolidCAD. “Liggo’s technology is designed to empower employees, streamline production, and scale operations efficiently, which aligns perfectly with SolidCAD’s mission to deliver cutting-edge solutions to our clients.”

This collaboration highlights SolidCAD’s commitment to equipping manufacturers with the tools they need to stay competitive in a rapidly evolving industry. By providing access to Liggo’s platform, SolidCAD customers can leverage advanced manufacturing solutions to reduce inefficiencies, optimize workflows, and drive greater business success.

About Liggo

Liggo is a shopfloor monitoring and management platform that connects users, machines, and systems to capture factory know-how and optimize production. With its comprehensive orchestration capabilities, Liggo empowers manufacturers to streamline operations, enhance collaboration, and scale their business value.