Automation is crucial in modern manufacturing, streamlining processes and enhancing efficiency. Despite its importance, there is a noticeable skills gap in the workforce’s ability to effectively utilize this technology. This gap not only infringes on productivity but also affects the industry’s capacity for innovation and competitiveness. An understanding of these issues sets the stage for exploring effective training and development strategies. Implementation of Industry 4.0 trends is helping partners achieve greater outcomes by leveraging all aspects of their daily operations.

Evolution of CAM

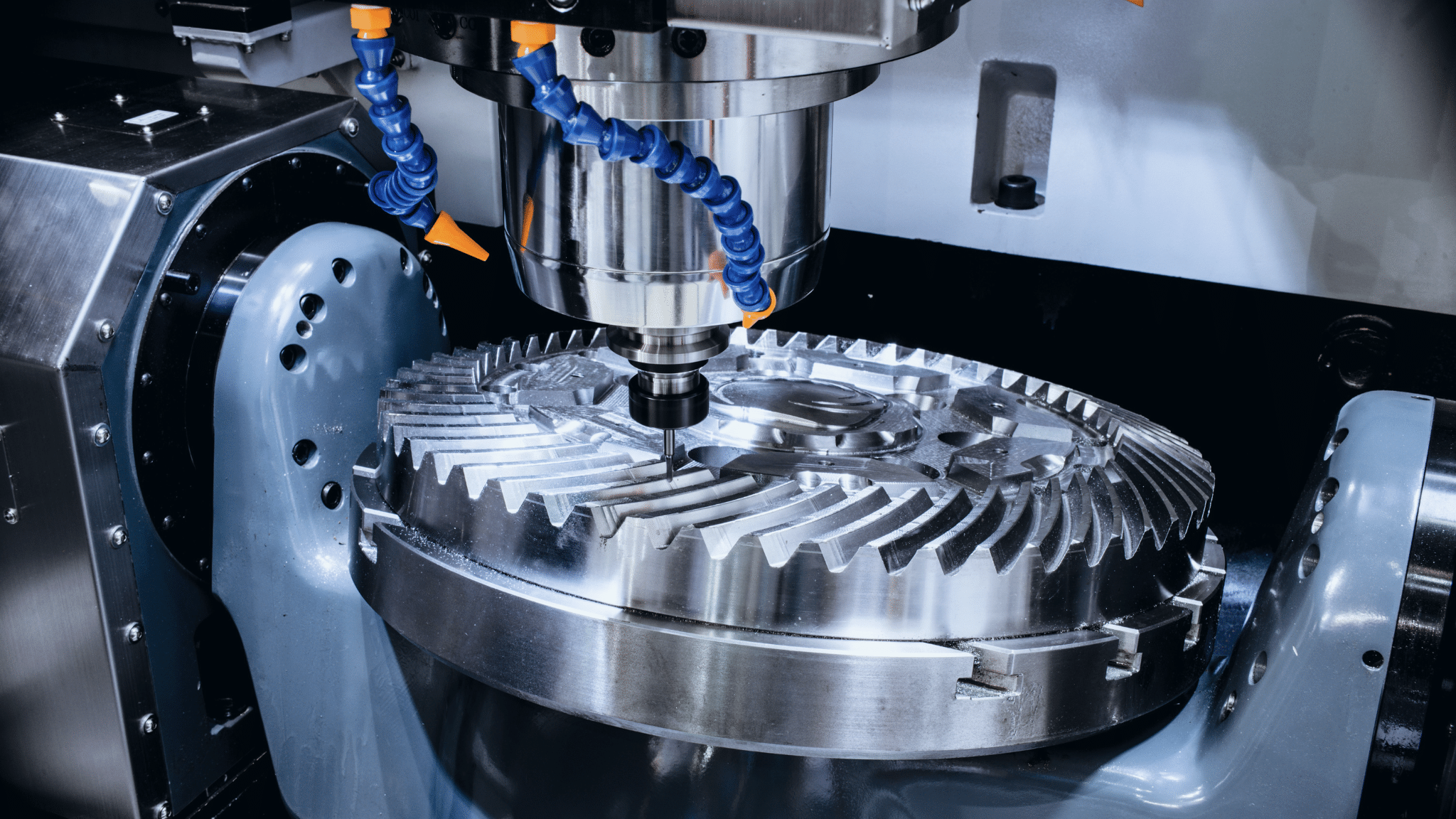

In the late 80’s early 90’s, creating a lathe bit for a specific application involved either making it yourself or consulting with a colleague. The drawer where these tools were kept often became so heavy that the rollers broke under the weight. This collection represented years of experience and countless hours of work.

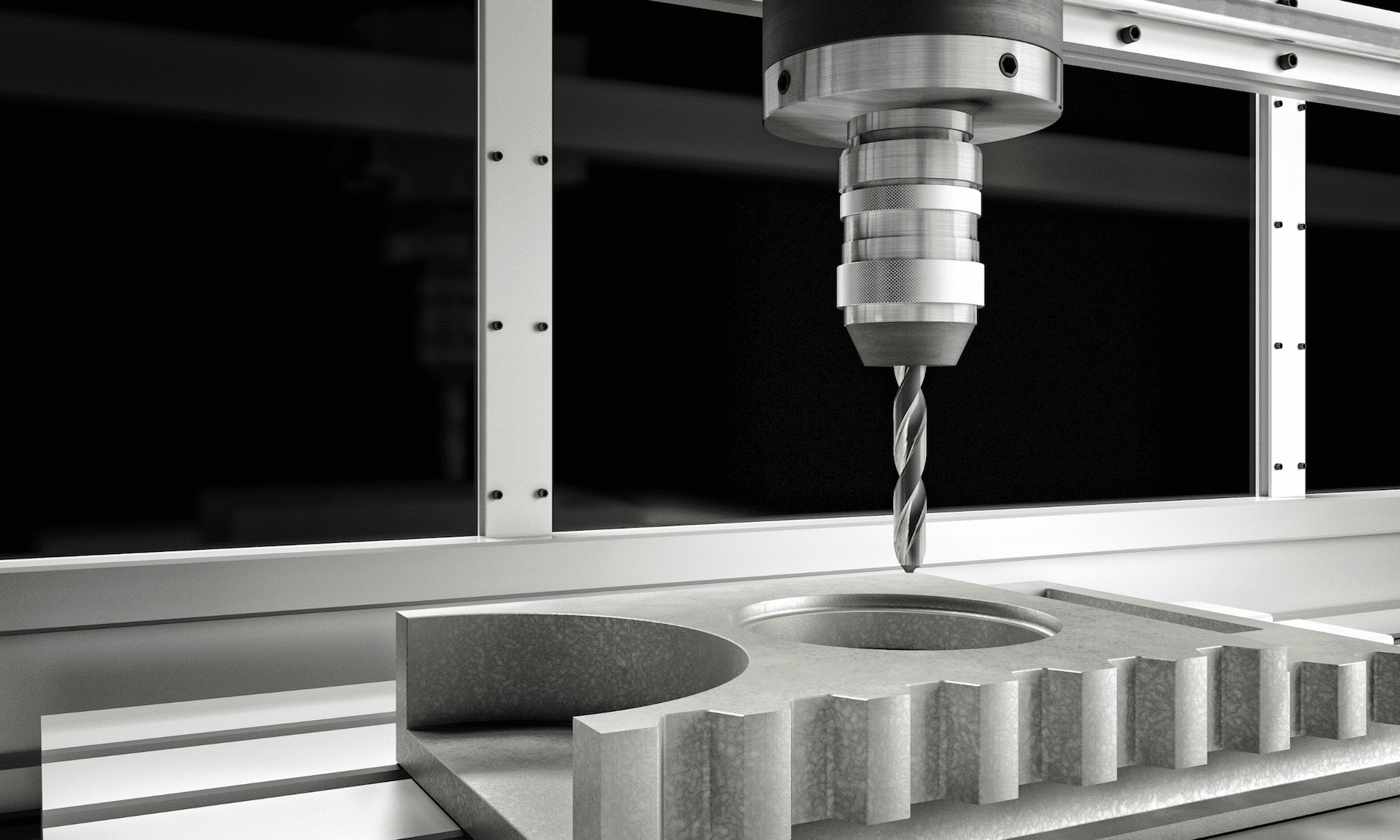

Initially, half-inch carbide blanks were ground down on a deckle wheel to make cutters for specific needs. Over time, machinists built their collections of carbide cutters, each created for a particular need, leading to heavy toolbox drawers. The days of programming directly on the machine controller and manually grinding down tools have largely disappeared. Today’s machinists rely on CAM software to create their programs. The art of 2D programming has evolved into 3D programming due to surfacing capabilities and time savings. As the industry has evolved, manufacturers have continually sought ways to improve their business operations but, to this day, filling gaps in the workforce that can keep up with the rapidly changing industry remains a key challenge for many businesses.

Strategies for Training the Workforce in Current and Emerging Software

Addressing the skills gap involves first assessing the specific training needs of the workforce through skills audits and feedback mechanisms. Developing a curriculum that focuses on critical CAM software like Autodesk Fusion can significantly enhance capabilities. Additionally, partnerships with educational institutions, software providers, machine tool partners, and industry leaders can help create comprehensive and practical training modules that are directly applicable to the industry’s needs.

As the industry has evolved and CAM has become increasingly important in manufacturing, there has been a focus on building upon current processes. Historically, most tasks were programmed with a CAM package, and automation was discussed but implemented differently. Today, forging holistic industry partnerships can create comprehensive and practical training modules.

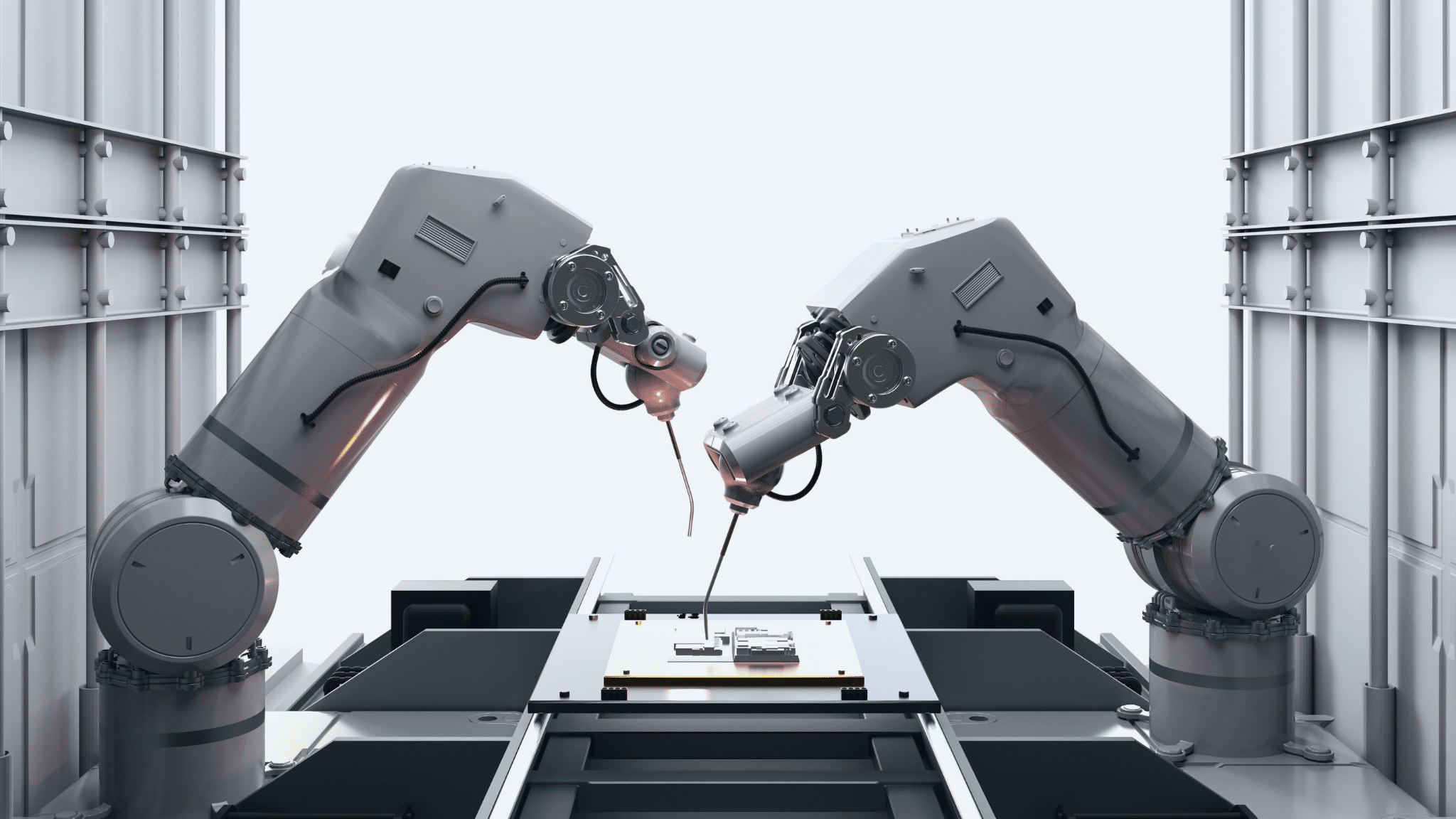

Before the current advancements, macros were created to assist with repetitive tasks, such as rest machining toolpaths and setting up programming sessions for new models. Today, there is a push to automate everything, developing processes to advance manufacturing and address the shortage of skilled workers. Automation now includes Artificial Intelligence and plugins to maximize efficiency while minimizing personnel requirements.

Tools and Technology to Streamline Processes

Incorporating automation tools such as Make Productivity, CloudNC, and OptiNC can address many common manufacturing pain points. Implementing them can increase both efficiency and accuracy, helping to meet the manufacturing needs of today’s machining processes and ultimately leading to greater sustainability. Integrating these tools into the workforce ensures that employees are proficient in modern technologies, preparing them for current demands and future advancements.

A notable example of successful workforce transformation is the case of Manufacture Scorpion. Through targeted training and technology adoption, operational efficiency was significantly enhanced. This case study, among others, provides valuable insights into effective strategies and best practices that can be adopted by other firms aiming to leverage CAM automation for business improvement.

Read more about Manufacture Scorpion’s success story here.

The Future of CAM Automation and Required Skills

The future of CAM automation is likely to be shaped by continuous technological advancements. As these innovations emerge, the industry must prepare a workforce that is skilled in current technologies and adaptable to future changes. This requires an ongoing commitment to training and development, ensuring the workforce remains competitive and capable of handling new challenges and opportunities in CAM automation.

Artificial intelligence is now a significant tool in the industry, changing the manufacturing landscape for future generations. With companies having facilities in various countries, efficient data exchange will be transformed by AI tools that strengthen customer relationships and service delivery. The future of CAM automation will be shaped by technological advancements, requiring a workforce that is adaptable and skilled in current and future technologies.

To learn more about training and other CAM automation services visit this link or reach out to info@solidcad.ca