Product Lifecycle Management (PLM) is a game-changer for businesses, especially for small and medium enterprises (SMEs). It’s all about managing your products efficiently from the drawing board to the customer’s hands. But, let’s be honest, implementing PLM isn’t always a walk in the park for SMEs. They face real challenges, from tight budgets to the daunting task of making big changes to how they operate.

Yet, the benefits of getting PLM right are too significant to ignore. It can streamline operations, boost product quality, and even speed up time to market. This blog dives into what SMEs stand up against when adopting PLM and how they can successfully navigate these challenges. We’ll look at practical strategies, cost-effective solutions, and real success stories to show that, despite the hurdles, PLM can be a powerful tool for growth and innovation in the SME sector.

Challenges Faced by SMEs in Adopting PLM

Implementing Product Lifecycle Management (PLM) in small and medium enterprises (SMEs) isn’t always smooth sailing. Here are the main roadblocks they often run into:

Limited Resources: One of the biggest hurdles is simply not having enough – whether it’s money, time, or staff. PLM can be a significant investment, and for SMEs watching every penny, this can be a tough pill to swallow.

Resistance to Change: Changing how things have always been done can meet with pushback. For SMEs with tight-knit teams, convincing everyone to adapt to a new system can be challenging.

Complexity of Solutions: PLM software comes with a lot of bells and whistles. For teams without a tech specialist, figuring out which solution fits best can feel like navigating a maze.

Integration Issues: SMEs already use a variety of tools and systems. Finding a PLM solution that plays nicely with existing setups is crucial but not always easy.

Tackling these challenges head-on is essential for SMEs to unlock the full potential of PLM. Up next, we’ll explore strategies to navigate these hurdles and make the PLM journey as smooth as possible.

Strategies for Successful Implementation

Overcoming the hurdles of PLM adoption might seem daunting, but with the right strategies, SMEs can navigate these challenges successfully.

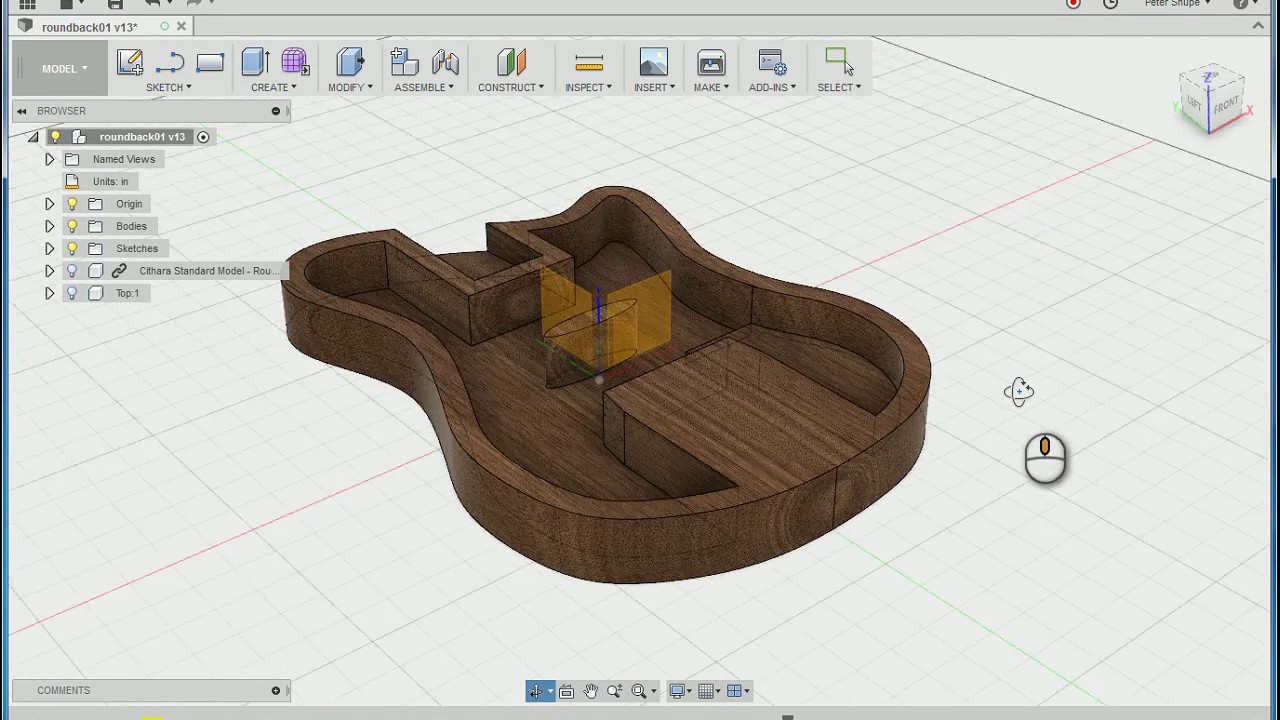

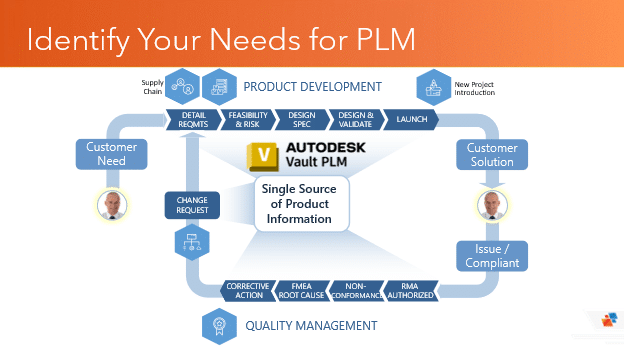

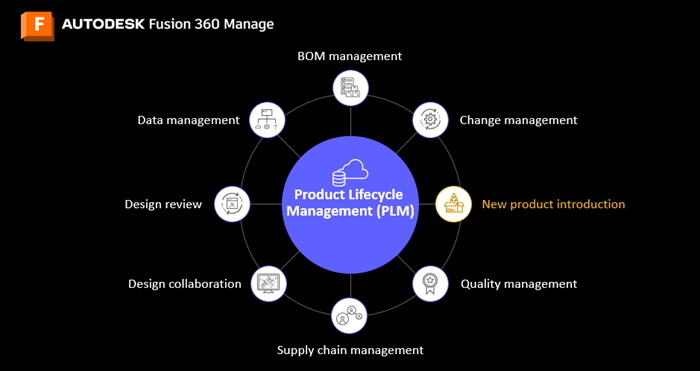

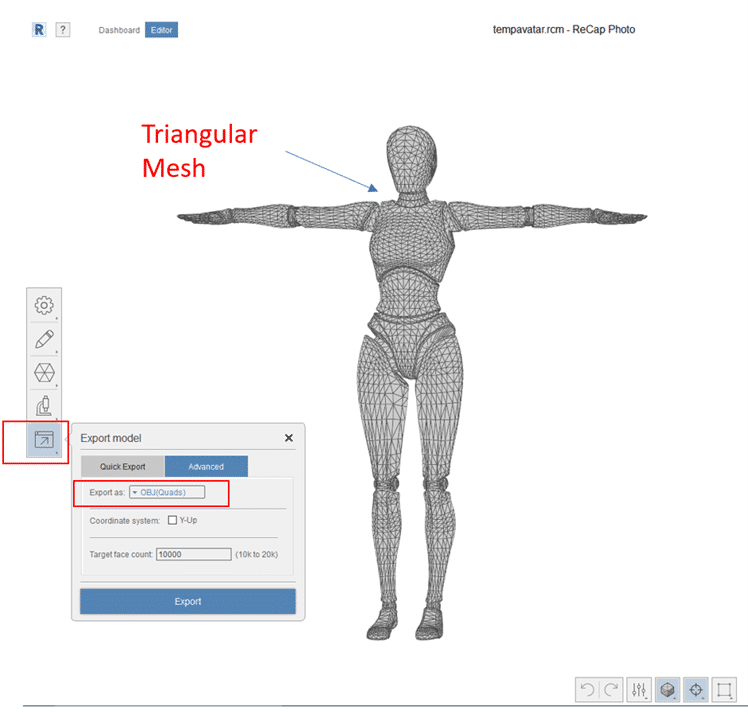

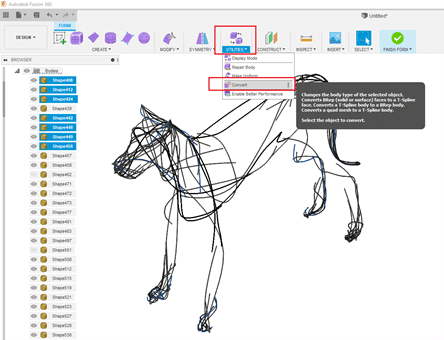

Conduct a thorough needs assessment before diving into PLM. It’s crucial for SMEs to understand exactly what they need from a PLM system for their business. With limited resources, it’s crucial to identify specific business processes that need improvement and any gaps in current systems. Typical needs SMEs have for PLM include Bill of Materials (BOM) management, change management (such as engineering change orders), project management, and quality management.

Figure 1- Map your business processes to pinpoint PLM needs, ensuring a tailored fit for your company’s workflow.

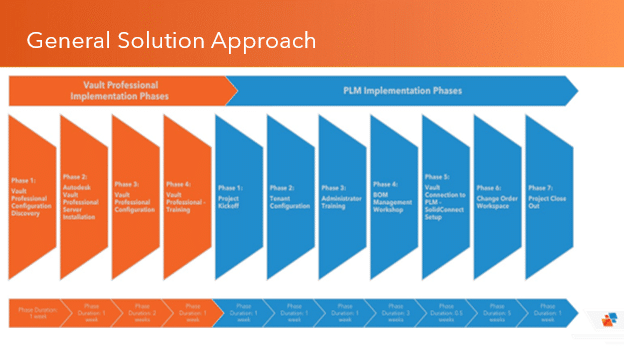

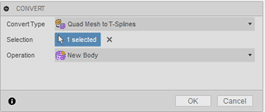

Consider using a phase-by-phase implementation for PLM. Trying to do everything at once can be overwhelming. Break down the PLM implementation into manageable phases, starting with the most critical areas. This approach reduces disruption and makes the transition smoother for everyone involved.

Figure 2-Implement your PLM with a strategic, phase-by-phase approach, prioritizing core business processes for maximum efficiency.

Invest in training for PLM. One of the best ways to overcome resistance to change is through comprehensive training. Ensure that everyone knows how to use the new PLM system effectively. This not only eases the transition but also helps in realizing the benefits of PLM faster.

Get professional assistance in implementing PLM. Not all PLM solutions are created equal, especially for SMEs. Look for a partner, specifically PLM specialists that understands the unique challenges faced by smaller businesses and offers scalable, user-friendly solutions. A partner that provides strong support and training for implementing PLM can make the process a whole lot faster and smoother to finish and is well worth the investment.

Look towards leveraging cloud-based solutions. Cloud-based PLM can be a game-changer for SMEs, offering flexibility, scalability, and cost-effectiveness. These solutions reduce the need for heavy upfront investment. Maintenance and updates are automatically pushed by the developers as well.

By tackling PLM implementation with these strategies, SMEs can turn the tide in their favor, ensuring a smoother adoption process and a quicker path to realizing the benefits of PLM.

Cost-Effective PLM Solutions

For SMEs, finding a PLM solution that fits both their needs and their budget is key. Here’s a list of items to consider when finding a cost-effective PLM solution:

- Consider “Service-as-a-Software” (SaaS) PLM Options: Subscription-based SaaS models are ideal for SMEs looking for flexibility and cost control. These models often include regular updates and maintenance, reducing the need for in-house IT support. SaaS PLM solutions ensure that SMEs can benefit from the latest features without additional costs.

- Look for Scalable Solutions: Choose a PLM system that can scale with your business. Initially, you might only need basic functionalities like BOM management and document control. However, as your business grows, you may require more advanced features such as project management and quality control.

- Assess the Total Cost of Ownership (TCO): Beyond the initial purchase price, consider the long-term costs associated with implementing and maintaining the PLM system. This includes training, support, customization, and upgrades. Go for solutions that offer a clear and predictable TCO, allowing for better budgeting and financial planning.

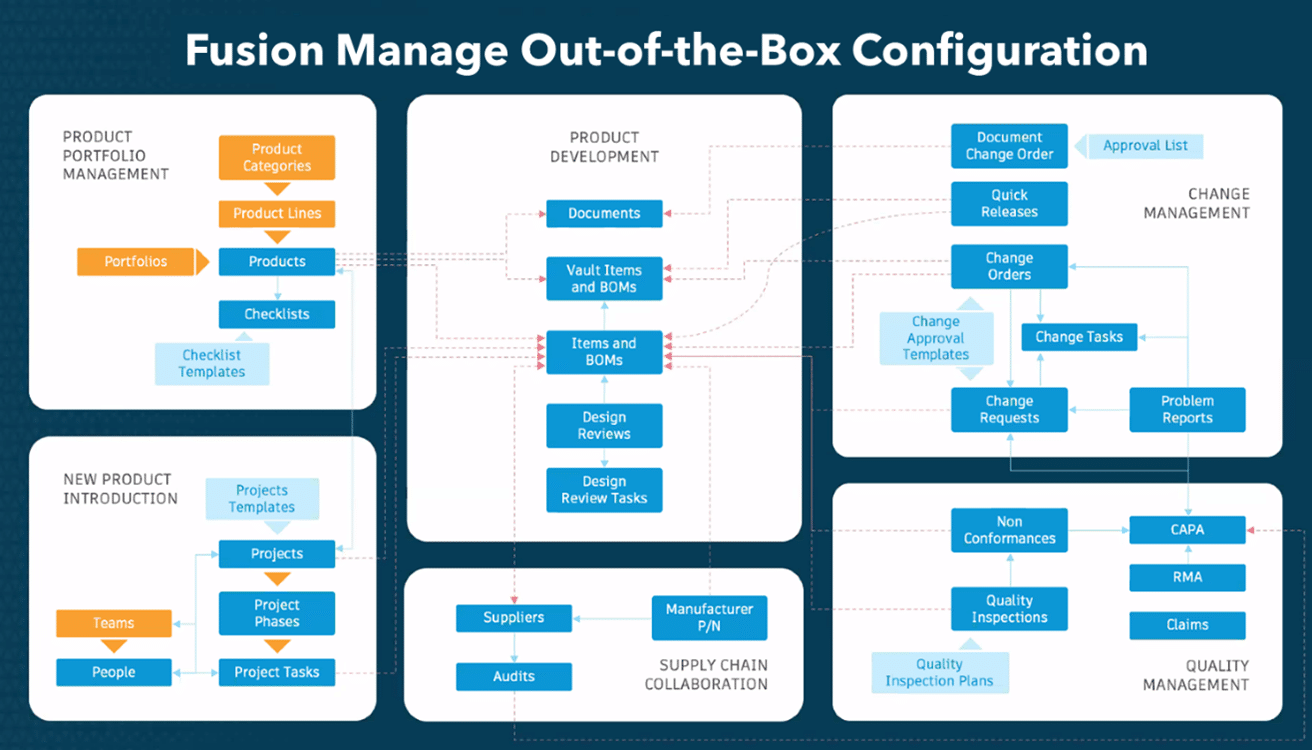

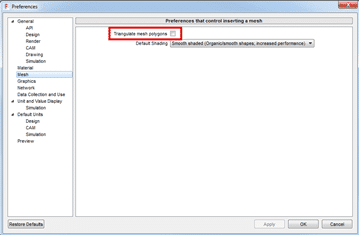

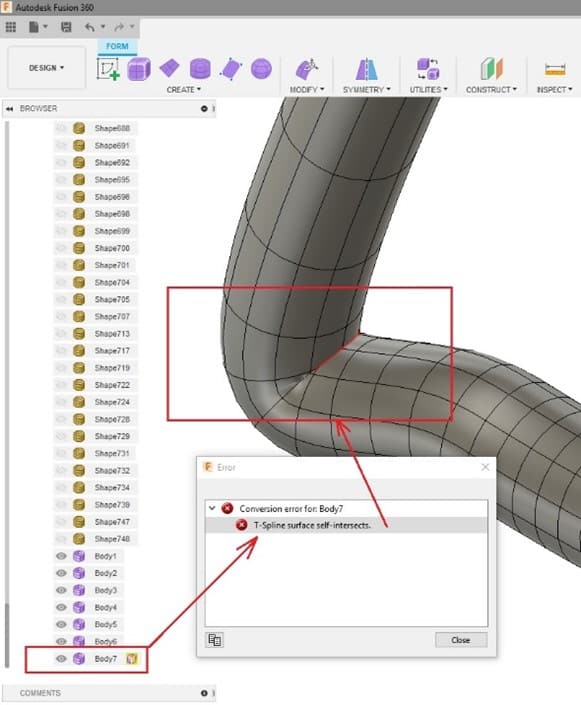

- Utilize Built-In Templates and Tools: Some PLM systems come with pre-configured templates and tools tailored to specific industries. These can significantly reduce the time and cost associated with customizing the system to fit your business processes. Look for PLM solutions that offer these out-of-the-box resources to streamline implementation and minimize costs.

Figure 3-Fusion Manage comes with a complete template solution to either fully adapt or partially.

By considering these factors, SMEs can find PLM solutions that not only meet their technical and business needs but also align with their financial constraints. Cost-effective PLM adoption is within reach, enabling SMEs to leverage the benefits of PLM technology to drive growth and competitiveness.

Case Studies Demonstrating the Impact of PLM on SMEs

D-Wave, a leader in quantum computing, partnered with SolidCAD to implement a scalable, cloud-based PLM system. The initial focus was on core functionalities like BOM and change management.

The results were significant: enhanced team collaboration, streamlined workflows, and a flexible system that grew with the company’s needs. This implementation not only improved D-Wave’s project delivery times and product quality but also set a foundation for sustained innovation and growth.

Until next time…

Until next time…