Overview

In today’s fast-paced and technology-driven market, managing the journey of a product from its conception through to its retirement is more critical than ever. This is where Product Lifecycle Management (PLM) comes into play, serving as the backbone for fostering innovation, ensuring quality, and shortening time-to-market. PLM is an integrated, information-driven approach aimed at enabling companies to efficiently manage the lifecycle of a product. It encompasses the coordination of complex processes, collaborations, and data management, from the initial idea through design and manufacture, to service and disposal of manufactured products.

Why investing in PLM is essential?

Investing in Product Lifecycle Management (PLM) is crucial as it enables organizations to navigate the complexities of product development with greater agility, ensuring that every phase of the product’s life from conception to discontinuation is optimized for efficiency, quality, and innovation.

Enhancing Collaboration Across Departments

Improve teamwork between different departments by bringing all the data together in one place. With PLM you can help teams like design, engineering, manufacturing, and service work together easily and more efficiently. By doing this, it helps make the process of developing products faster and ensures that everyone is working towards the same goals.

Streamlining Process Efficiency

PLM systems boost efficiency by automating workflows, reducing time and costs in product development. This ensures quick updates and access to the latest information, leading to higher quality products and faster market entry, giving your business a competitive advantage.

Mitigating Risk and Ensuring Compliance

PLM is crucial for risk mitigation and regulatory compliance, offering improved oversight and control throughout the product development cycle. This ensures adherence to industry standards, preventing costly recalls and guaranteeing that products satisfy both consumer and regulatory demands.

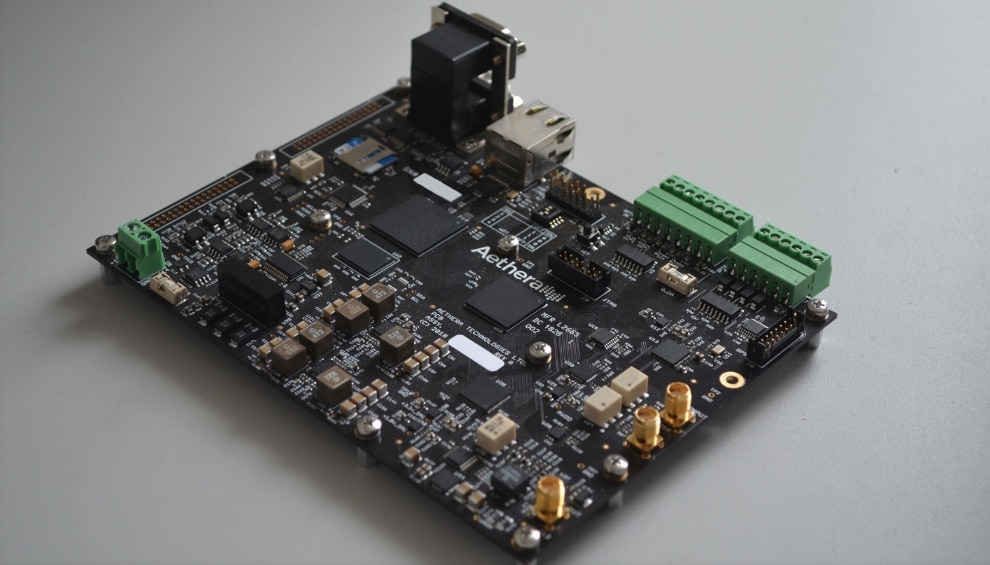

Software Technology

Managing documents, 2D and 3D CAD data and engineering information can be difficult. Especially, in a market where everyone needs customized projects and products.

Autodesk PDM & PLM is a cloud based solution that helps you manage your data, documents, BOMs and keep track of everyday changes. It connects your entire enterprise, across departments and geographies, to get your products to market faster. Learn more about Fusion 360 Manage.

Our Recent Success

These real-life cases illustrate how we’ve empowered businesses to streamline their operations, breaking down silos and enhance interdepartmental communication. Each story is a testament to how our strategic approach has not only solved complex issues but paved the way for seamless and productive workflows.

Resources

Featured

Blogs

Additional resources

How Our Organization Can Propel Your PLM Journey

Our team is all about teamwork and making PLM technology work seamlessly for you. We dive deep into your organization's needs, crafting strategies that enhance your workflow and push forward digital transformation. We’re here to simplify the complex world of product management, ensuring your processes are efficient, compliant, and cutting-edge. By choosing us, you're not just adopting a system; you're embracing a partnership that elevates your product development to new heights of innovation. Let's work together to make your products stand out and your business thrive in today's competitive landscape.

Common FAQ Questions: PLM

What is Product Lifecycle Management (PLM) software?

Product Lifecycle Management (PLM) software is a business strategy and digital platform that manages every stage of a product’s lifecycle from concept and design to manufacturing, service, and retirement. It creates a central, secure hub for product data and processes, enabling faster collaboration, reducing errors, and improving time-to-market.

What’s the difference between PLM and ERP? Do manufacturing companies need both?

PLM software focuses on product design, engineering data management, change control, quality processes, and supplier collaboration. ERP (Enterprise Resource Planning) manages inventory, procurement, production, and finances. For most manufacturers, PLM and ERP work best when integrated to deliver a seamless flow of information from design to delivery.

How can PLM improve manufacturing processes?

PLM centralizes design files, BOM (Bill of Materials) data, and engineering change orders, ensuring all departments work from the same information. This improves product quality, shortens design cycles, ensures regulatory compliance, and streamlines communication with suppliers and partners.

Is PLM only for large enterprise manufacturing companies?

No. Modern cloud-based PLM solutions are scalable for small and mid-sized manufacturers. You can start with essential PLM features such as BOM management, document control, and change management and expand as your operations grow.

How long does it take to implement PLM software?

Implementation timelines depend on the scope and complexity of your PLM project. Many small to medium-sized manufacturers can launch a first phase within 8 to 12 weeks, then roll out additional capabilities in phases to ensure user adoption.

Can PLM integrate with CAD and ERP systems?

Yes. PLM integrates with popular CAD tools such as Autodesk Inventor, AutoCAD, and Fusion 360 and ERP systems to ensure data flows between design, engineering, manufacturing, and operations. SolidCAD specializes in building integrations that work with your current processes.

How do I measure the ROI of a PLM system?

Key performance indicators (KPIs) include reduced engineering change cycle times, faster time-to-market, fewer product defects, better on-time delivery rates, and lower manufacturing costs. SolidCAD helps you track these metrics to demonstrate measurable PLM ROI.

What are the benefits of cloud-based PLM compared to on-premise solutions?

Cloud PLM offers faster deployment, lower upfront costs, automatic updates, and easier scalability. It also supports remote teams and suppliers with secure access from anywhere, making it ideal for manufacturers with distributed operations.

What challenges can PLM help solve for manufacturers?

PLM addresses common challenges such as disconnected design and production teams, version control issues, compliance risks, delayed product launches, and misaligned supplier communication. By connecting data and processes, PLM reduces costly errors and rework.