TORONTO, ON, August 1, 2017 – Cansel has been a successful Autodesk Platinum Partner, supporting customers across Canada for all of their software and professional service needs, for over eight years. In 2015, Cansel merged its Ontario Autodesk business unit into SolidCAD. Today, SolidCAD and Cansel announce the consolidation of their national operations forming the largest Canadian Autodesk Platinum Partner, newly branded as SolidCAD, a Cansel Company.

“SolidCAD and Cansel have been two of our most valued resellers in the Canadian market,” states Marcus Tateishi, Senior Partner Manager at Autodesk. “The strength of these highly specialized teams now working as one will be a benefit to our mutual customers. This new partnership provides expert personnel committed to the Autodesk product portfolio across the country and is an investment we are proud of.”

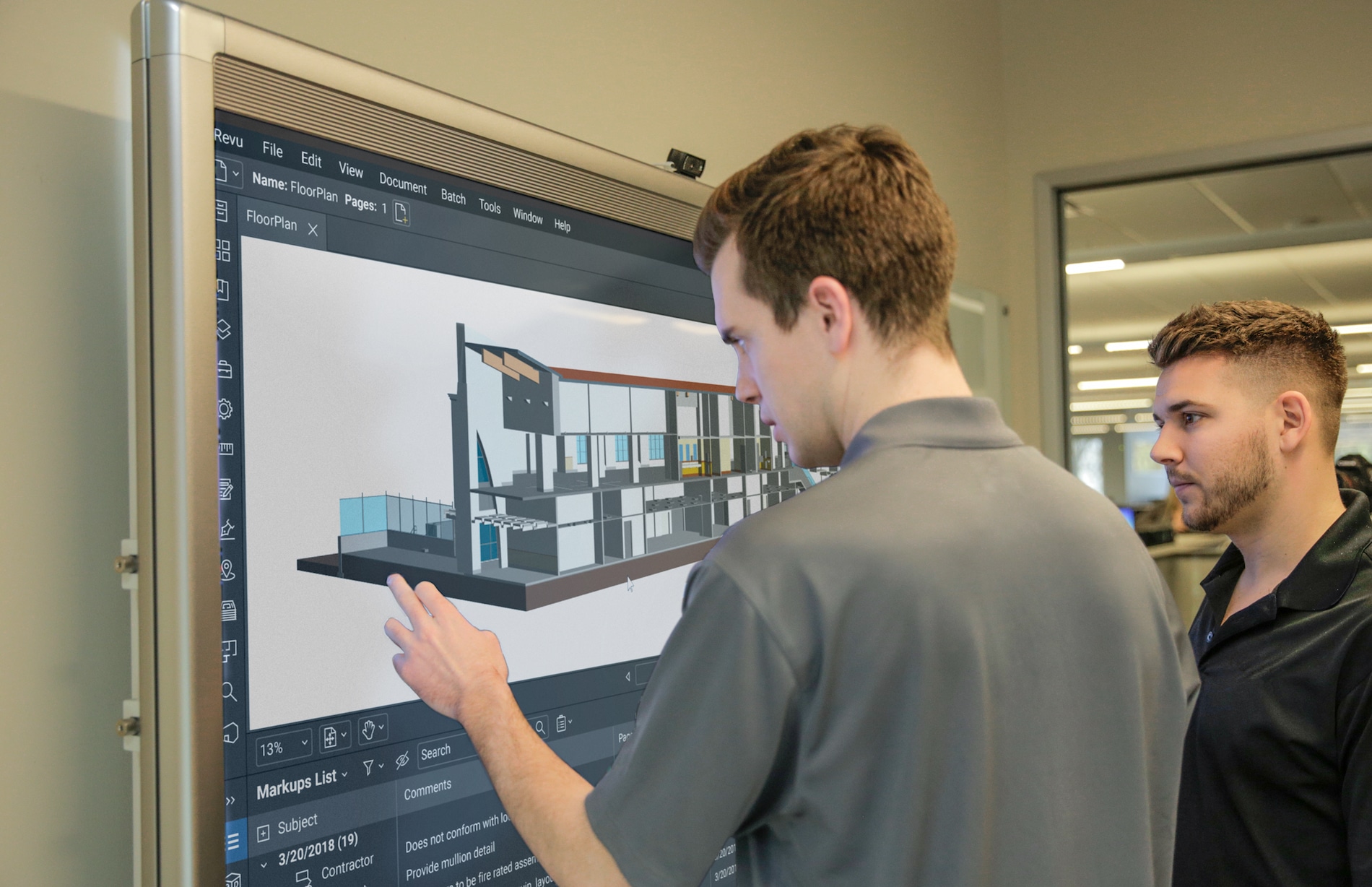

With over ten offices across the country, SolidCAD is now the only national Autodesk reseller owned in Canada, operating in both official languages. This transition to one single business operation demonstrates Cansel’s dedication to both their clients and Autodesk. The Canadian market benefits by the development of SolidCAD, a Cansel company, a team dedicated solely to providing the best range of products and services to their customers nationwide. Now with an even stronger combined team of over 40 technical consultants across the country, SolidCAD and Cansel are devoted to helping firms overcome challenges with design, production, collaboration and project deliverables.

“Having worked closely with SolidCAD since the 2015 merger of our Ontario Autodesk business, we are eager to bring this newly combined organization to the marketplace in Canada.” said Stephen Fletcher, Vice President, Cansel. “This milestone represents the opportunity to bring a broader product portfolio and depth of expertise to our clients and confirms our investment in providing top quality customer service.”

“We are very excited for our organization to form a national presence,” states Michael Kugan, President at SolidCAD. “With over 28 years of experience streamlining processes and optimizing Autodesk technology, we look forward to offering increased value to our clients by delivering high-quality solutions in all time zones, and in both official languages.”

FAQ

About Cansel

For over 50 years Cansel has helped organizations in the engineering, surveying, construction, mining, architecture, manufacturing, printing, utilities, forestry and government sectors measure, analyze, design, and build more efficiently and profitably. Cansel’s national team of professionals combine software, hardware and services to provide tailored solutions to improve your workflow, from field to finish. www.cansel.ca