This article was originally published by Bluebeam, Inc. on the Bluebeam Blog.

ne of the downstream effects of the 2020 COVID-19 pandemic has been a strong projected uptick in cloud software conversions. With employees increasingly working remotely, software needs to be available anytime, anywhere. Software doesn’t have to be cloud-based to be remotely accessible, but many chief information officers (CIO), even at midsize companies, have had cloud transformation on their roadmaps, and the pandemic has provided the occasion to ask: if not now, when?

Moving key software applications to the cloud, which has already taken place across the construction industry, will have significant implications for the organisation – most obviously on the IT team that has been maintaining the software on-premises. In financial terms, the cloud-based construction management software transformation is a change from licensing software and paying annual maintenance fees to an on-demand and pay-as-you-go model. You rent the application instead of buying it.

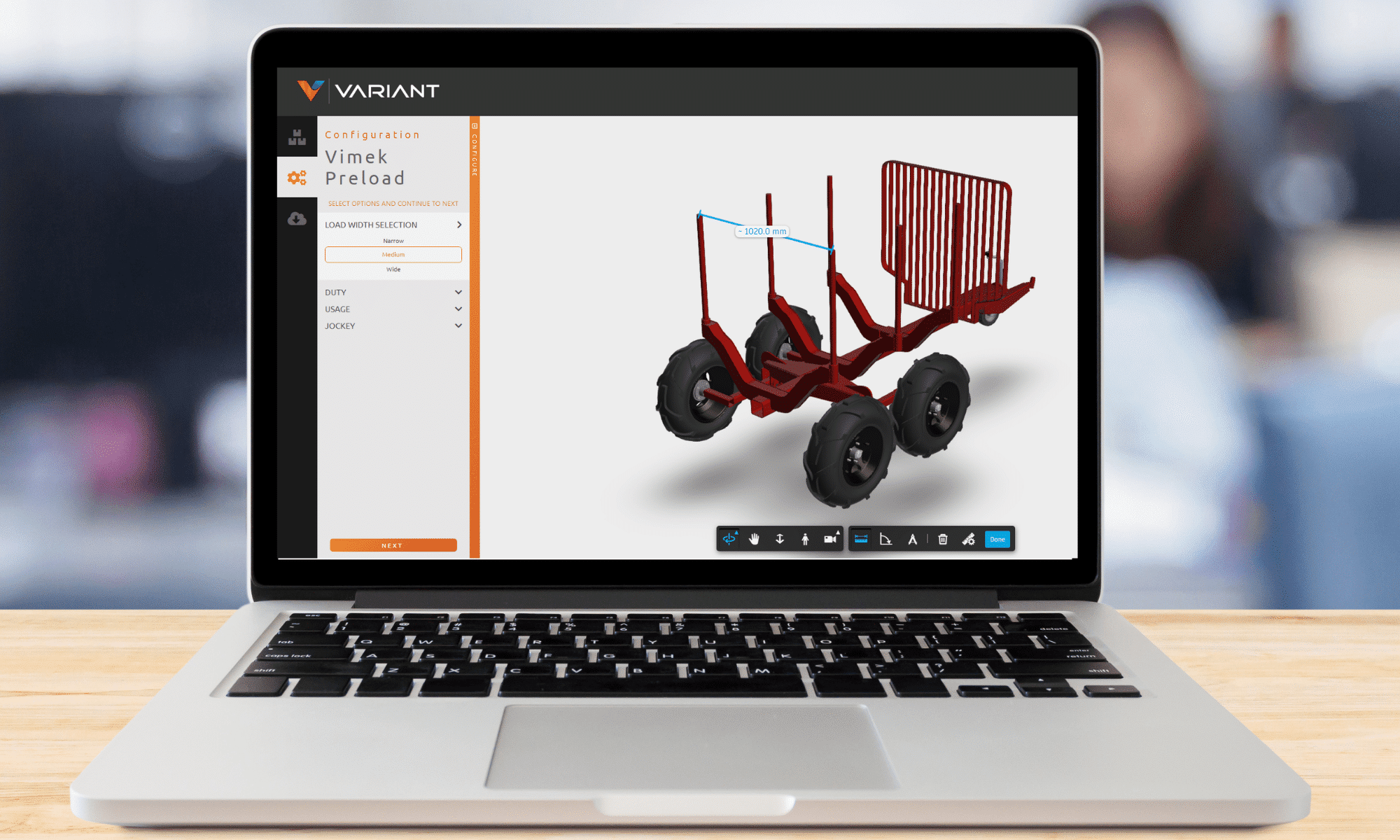

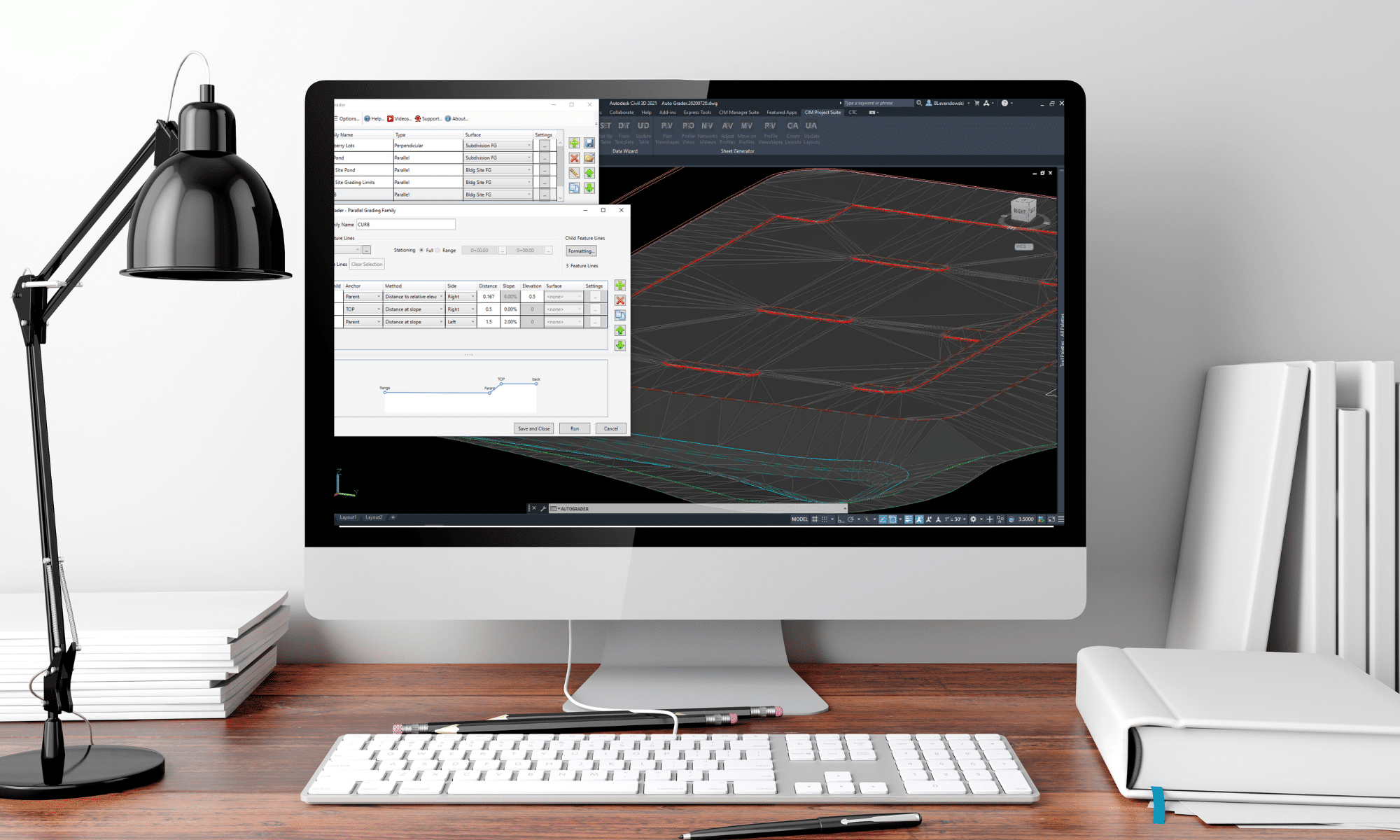

For end-users, a smooth cloud migration may be almost imperceptible. For instance, a user logs in to their cloud-based construction software application, works with colleagues on finalising a set of documents for a large office building project and passes them on for approval without even a hint of consideration of the technology making that series of interactions possible.

Here are answers to common questions construction professionals may have about cloud collaboration in the construction industry and the technology behind it.

Where’s my software?

It’s not on your computer anymore. It’s on a remote server, being delivered to you whenever and wherever you need it. Is that something to be concerned about?

According to Jim Prothe, marketing director at Magenium, an IT solutions consulting firm based in Glen Ellyn, Illinois, there are good reasons to be excited about the change.

‘A friend of mine has a business that rents an office in a Chicago suburb’, Prothe said. ‘Last summer, another tenant in their building had a fire over a weekend. All the sprinkler systems turned on, and the application server was toast. They had to spend the next two weeks rebuilding that server from month-old tape backups. So, they lost a month of data, including all their billings. If they’d been operating in a cloud environment that had an outage in a region, they’d have had built-in failover capacity; they would have been able to spin up capacity in another region, and their business would never miss a beat.’

Where is this server?

It’s no longer in the company’s server room – or, in cloud computing parlance, it’s no longer ‘on-premise’. Where it’s situated depends on where your business is located and what kind of cloud you’re using.

What kind of cloud?

There are at least three different kinds of cloud service infrastructure that drives cloud collaboration in the construction industry:

- Public cloud: You, the end-user company, are renting services from a large vendor, perhaps even a global enterprise like Microsoft Azure, Amazon Web Services or RackSpace. Typically, your company is sharing the rented infrastructure with other companies (what the vendor calls ‘tenants’). Your applications and your data are architecturally walled off from those of other tenants, but the bits are located on shared machines. In the early days of cloud adoption, some tenants worried about the possibility of proprietary data bleeding over into other tenants’ spaces. But growing confidence in providers and in cloud technology has generally done away with that concern.

- Private cloud: This generally refers to an infrastructure with all the characteristics of cloud architecture, but one built and maintained by your company. Large enterprises may prefer a private cloud for extremely sensitive data. It’s an exceptional situation for a mid-sized architecture, engineering or construction firm.

- Hybrid cloud: Some organisations maintain applications in both public and private cloud infrastructures.

As an end-user, the type of cloud probably won’t affect the availability or performance of the software.

What are we getting from the server?

There are at least three different levels of commitment your company could make to its cloud transformation:

- Infrastructure as a Service (IaaS): Your company rents physical space on the provider’s servers and relies on the provider to keep them running. But that’s it – your own IT people set up and maintain all the software.

- Platform as a Service (PaaS): In addition to the hardware, the provider maintains the operating system and all the other architectural features of the environment. Your people still maintain the applications.

- Software as a Service (SaaS): The provider maintains everything from the operating system to the applications; your company pays to use these services on an as-needed basis.

Where’s my data?

Some of it is local – but the bulk of it is in the cloud. The physical location of the server generally makes little or no difference to the end-user, other than in exceptional circumstances involving regulatory compliance. Under Sarbanes-Oxley regulations, enacted after the Enron accounting scandal in the early 2000s, financial services firms often need to be able to specify to regulators where their account data is being stored. Other regulations come into play if they operate internationally. You can ensure, contractually, that your data stays within a certain region or on a certain server.

The server’s physical location isn’t entirely irrelevant when it comes to cloud collaboration in the construction industry. The speed at which data packets travel their tortuous routes across the internet is breathtaking, but if the server is far enough away, the end-user will experience a noticeable performance lag. This is why public cloud providers – and large organisations that host their own private clouds – have multiple, redundant servers distributed among regions. The infrastructure will be designed to route your data through the nearest server and to reroute to the next-nearest server if your region’s system goes down.

‘Generally, the large cloud service providers give you the option to choose the region where your primary servers will be located’, Prothe said. ‘Nearly every metropolitan area will have its own dedicated servers.’

Why are we using cloud software?

In the short run, it’s cheaper to rent than to buy. The SaaS provider can price services inexpensively because it enjoys huge economies of scale.

From an accounting standpoint, there are benefits in reducing capital costs and increasing operating expenditures. Cloud service contracts generally come under operating expenditures. ‘During the 2008 financial crisis, capital budgets evaporated’, Prothe said. ‘Businesses still had to operate and moving applications to the cloud was one way to keep going. In some industries, we’re seeing the same thing happen because of COVID.’

Renting cloud software reduces the burden on a company’s IT services, because it has less infrastructure to maintain. ‘A friend of mine who runs an HVAC engineering company complains about the burden of supporting on-premises software’, Prothe said. ‘It constantly needs to be patched, and each time that introduces a new security vulnerability. The investment in IT resources to manage those changes is pretty daunting for a small engineering firm.’

Isn’t this risky for our secret stuff?

Some companies express concerns about their most sensitive data, but the cloud can be more secure than having your own data centres.

A global company like Amazon Web Services or Microsoft may have thousands of full-time security people, assisted by artificial intelligence tools designed to spot or even prevent service interruptions or hacker intrusions. Their automation tools can detect unusual activity across the network, such as odd data traffic, and analyse it quickly to size it up as a potential threat. And, of course, traffic over cloud networks is encrypted end to end. The provider’s reputation is riding on the strength of that encryption.

‘Your instinct may tell you to maintain close control over important applications’, Prothe said. ‘But you need to ask yourself who is better at maintaining a secure infrastructure – a cloud service provider whose survival depends on their reputation for security, or your IT guys?’

There must be a downside to cloud adoption, right?

There is one, obvious downside: users need to have a reliable internet connection.

Still, start-up costs are cheaper, although cloud software can cost more in the long run. ‘We have a lot of companies move applications from on-premises to the cloud, and they often need help optimising their spend’, Prothe said.’“You can spend a lot of money quickly in the cloud. You spin up a lot of power, and you pay for it on a monthly basis, so you may not notice it. You can often dial down the power you consume during off-hours when people are less likely to be online.’

If the data structure in the cloud application is different from that of the on-premises software, the data may have to be cleaned up, restructured and normalised. Migrating data to the cloud can be expensive, cumbersome and risky if undertaken without expert help.

Is everybody moving to cloud software?

It depends. Some companies are using only the basic applications like email in the cloud; some are ‘cloud-first’ – the default, when introducing a new application, is to adopt the cloud version.

It also depends on the application. Many software companies are themselves moving to a cloud-first product development roadmap, gradually transitioning their long-time customers from on-premises installations to their cloud offerings. Many new software vendors are likely to be cloud-only.

So, the next time you log on to use any cloud-based application to review a design or communicate a set of document changes, now you know how the technology behind those transactions truly works.

The Setting

The Setting

Until next time…

Until next time…