This story was originally published by on the Bluebeam Blog.

Despite the temptation to implement new technology quickly, it’s important that there are practices in place to ensure the tool is evolving in the long run.

ost construction industry leaders would likely agree that implementing new technology can be a complicated process.

From identifying pain points to researching possible solutions to going about the lengthy process to test and implement the new technology, the process can be painstaking—even though such efforts have largely gotten relatively easier and more accessible recently.

Still, it’s important for construction leaders to remember that any new technology implementation is a marathon, not a sprint.

While many focus on the initial dash to become operational on new technology, it’s critical to account for long-term considerations. Even once the initial phase of implementation is complete, seemingly solving the problem, it’s worth maintaining a continuous-improvement approach.

Here are six things construction leaders can do to ensure they’re taking the long view when implementing new technology.

Make training continuous

It’s easy to focus on the initial implementation training when installing a new technology. Construction leaders have by this point spent months (or even years) researching the new tool and orchestrating its implementation.

Yet, there are several reasons why training should be designed as a continuous, long-term process.

No matter how well-designed your initial technology implementation training may be, people aren’t likely to retain it all the first time around. Often when taking on new technology, people don’t know what they don’t know—so they retain what’s taught to them just to get by, without fully realizing the context of the tool.

Revisiting concepts taught in the initial training may be helpful several months after the implementation training. Then, as time passes, additional ongoing training should take place about new features and tools.

Appoint technology champion(s)

It’s likely that the initial technology implementation featured a leader or group of leaders responsible for the complex process of overseeing the effort and all its components. This leadership structure should persist long past the initial implementation.

Depending on the size of your company or team taking on the new technology, this can be one person or several people. A large municipal department, for instance, may appoint a council of strategic advisors to oversee and maintain the long-term efforts associated with new technology implementation.

These people should meet regularly to craft new training and other initiatives to ensure that the technology’s use is progressing. They should also come from different divisions or disciplines across a company to ensure every perspective is represented.

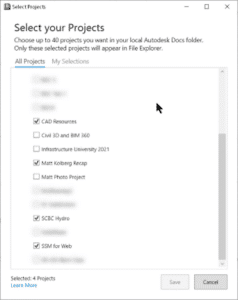

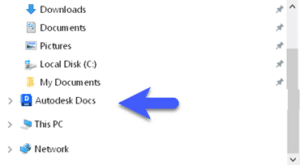

Initiate internal user groups

A great way to embrace a continuous-improvement approach to a new construction technology implementation is to form an internal user group. This group is designed to meet regularly to share knowledge of the new technology and explore new possibilities of how the tool can be used.

Perhaps the best way to make these groups effective is to make them social as well. Have them meet after working hours so they feel more informal and community-oriented, rather than just another meeting during the workday.

Devise external knowledge sharing

Equally as critical may be coming up with ways for external knowledge sharing on new technology. While internal user groups are tremendously effective in expanding a company’s use of new technology over the long term, it’s important that construction firms have a way to bring in external knowledge, too.

Attending or organizing industry events on new technology, or starting one that brings in like-minded users from other organizations, are all ways to channel external knowledge that will pay dividends long into the future.

Conduct regular technology audits

No matter how long a tool has been in place and how knowledgeable people may be on it, construction leaders should get into the habit of conducting regular, formal audits on the technology. Whether you bring in an outside group to conduct the audit or use your internal technology leadership team, doing this ensures that the technology remains effective at improving your firm’s efficiency and solving new problems that arise over time.

Embrace failure

Don’t worry if everything isn’t perfect. New technology implementations can be messy. Try to embrace the small failures that will inevitably come, allowing you to iterate to ultimately maximize the value of the new technology. After all, such failures are often the best learning opportunities.