Are you designing a pond with a sloped bottom? If so, you may be interested in this technique.

To watch the short video demonstrating the complete quick step-by-step process, click here.

Are you designing a pond with a sloped bottom? If so, you may be interested in this technique.

To watch the short video demonstrating the complete quick step-by-step process, click here.

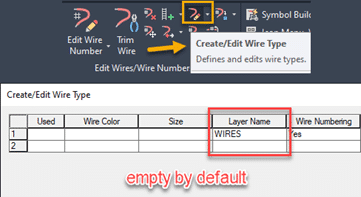

Whenever we are working with AutoCAD Electrical, one of the key features that we have when we are creating our drawings, is the ability to

create and assign the custom wire types that we will use throughout our schematic designs. Every time that we create a new drawing, by default the only wire that is going to be available is the WIRES layer which is the generic wire type that the software uses when we first create any type of wire as displayed on Figure.1 in the Create/Edit Wire Type editing window.

Having to manually enter the types of wires that we are going to use is a task that cannot be avoided the very 1st time that we create a drawing, but once we having created the list of wires that we need to use in one drawing, we can reuse them over and over again.

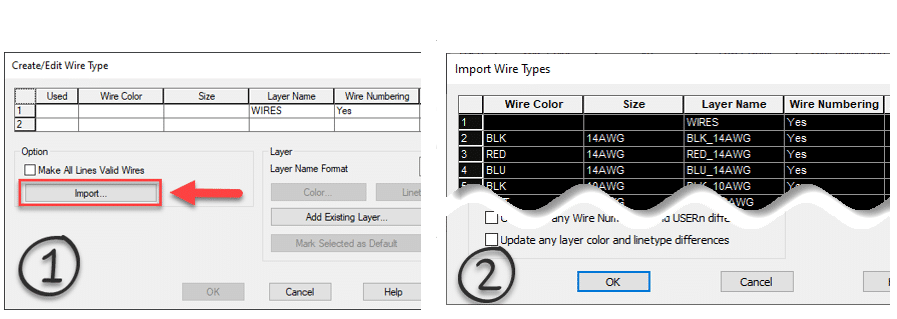

To achieve this we need to do the following:

Figure 2To take this one step further, we can standardize the wires that we use with your CAD Manager so we can import that list of wires directly into your templates. To achieve this we need to open the current template as a DWT file, then repeat the exact same process that was described earlier.

Once we have completed importing all the wires we need to re-save the template as a DWT one more time to make sure it will be usable as a template in the future.

This will further standardize the wires that the designers are required to use and remove the guess work by setting the wires at a template level.

This story was originally published by DOMONIC DIAZ-WESTON on the Bluebeam Blog.

Every construction trade plays a different role in each construction project. As a result, they are likely to find different values in the myriad tools and features available in Bluebeam Revu.

Kaaron Lee-Wah, an electrician in Toronto, is no different. To him, Revu has become essential ever since his boss asked him to explore how to completely digitize his company’s electrical drawings from paper. Revu has allowed him to use tools in the software that make his job more efficient, helping him to save time on previous paper-based tasks.

These are the Revu features that are unquestionably Kaaron’s favorite:

Tool Chest: “This allows you to create custom icons to help identify and create a clean and easy layout for your guys in the field to follow along. When it comes to electricians using Bluebeam, there are many different panels, circuits and devices that we have to account for and include on our drawing. With Tool Chest, you can create icons, color whatever size you need it, all in a matter of seconds—and they look very professional.”

Calibrate: “The Calibrate feature is pretty dope, where you’re able to upload a PDF version of any drawing—whether it be mechanical, architecture, electrical, even landscape—and you can customize that calibration to that specific scale. So, drawings come in many different scales, and other software have a hard time picking up and reading that scale of a drawing. But Bluebeam has a great feature, the Command + M tool, that can measure it, and you’re able to customize and calibrate any drawing or PDF you upload into Bluebeam, which gives you access to finding whatever measurement that you need—whether it be in millimeters or meters or feet—all off the custom calibration once you upload it into your Bluebeam Revu.”

Overlay: “It’s kind of similar to Snapshot, but with Overlay you’re able to grab the entire page itself and overlay it on top of a second set of drawings, and then that can help you identify or troubleshoot any issues with architecture and electrical drawings.”

Snapshot: “I find with Snapshot you’re able to now copy a section—let’s say the electrical drawings—and bring them over to the architectural drawings if you want to overlay for a certain reason. So, what we do in the electrical trade is I’ll take a Snapshot of the electrical drawings of let’s say a unit in a condo, and I will overlay it on the architectural drawings, which show you more detail—wall sizes, how long a wall is, how deep the wall is. It’s an amazing feature, and it comes in clutch every time.”

Watch on YouTube https://www.youtube.com/watch?v=zAkD-l8v_m8

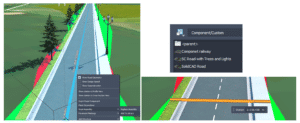

It’s relatively easy to create a custom component road assembly within an Infraworks model. But how does one save that custom assembly for use later? Read on to find out!

The answer depends on how you’d like it to be shared:

First, to save a custom assembly, simply right click the component road and choose Add to Library. Choose a station to copy and give the new assembly a name. The new assembly will appear in the style palette.

Choose a station to copy and give the new assembly a name. The new assembly will appear in the style palette.

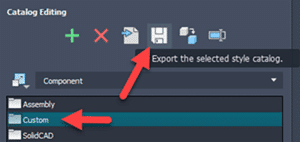

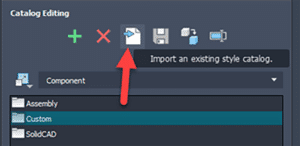

The individual assembly cannot be exported, but the catalog can. Select the catalog, in this case, Custom, and click to export to a JSON file.

The JSON file can then be imported into a different existing model using the import button. The assembly will be available in the styles palette.

There is no “tool” for this, but if one copies the appropriate files from and to the correct locations, then it works just fine. The custom assembly files can be found in the model’s folder path.

…model.files\unver\Content\Styles\Component\ . Possibly in a Custom sub-folder.

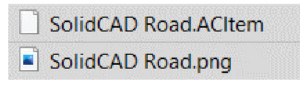

There will be 2 files for each assembly. A PNG image and a ACItem file.

Copy these two files to the Infraworks standard folder. Feel free to create a sub-folder here to place your custom assemblies. This folder will appear within Infraworks.

C:\ProgramData\Autodesk\InfraWorks\Resources\LocalLibrary\Styles\Component\

The JSON file can then be imported into a different existing model using the import button. The assembly will be available in the styles palette.

CMAC-Thyssen Mining Group is a contractor and mining equipment manufacturer offering a diverse range of fully integrated services with contracts carried out across multiple continents and over 850 employees worldwide. CMAC-Thyssen Mining Group makes the mining profession accessible through their unique training program, mechanized equipment, solid partnerships and innovations.

They have been working with SolidCAD since 2015 and maintain a strong relationship to this day. Being such a prominent company in their industry, CMAC-Thyssen stays up to date with the most efficient software and training to help them succeed.

Due to their vast international client base, CMAC-Thyssen accrued a tedious amount of paper data. The production team was unable to access drawings without help from their engineering department. This ultimately slowed down their workflow as their engineers became overwhelmed with the huge amount of information and lack of resources to efficiently store it.

CMAC-Thyssen reached out to SolidCAD to streamline their processes and improve data management. Our team of industry professionals was able to assess their needs and implement AutoCAD, Vault and Inventor to help bring their data into the digital world. Rather than speeding up the processes they had in place, our technicians helped them rethink their processes altogether and streamline their entire workflow through organized and accessible data.

SolidCAD does their job very well, we have a good relationship with them. Their technicians helped us with implementation and are an integral part of the team. There has been a lot of collaboration and it is very appreciated on our part. I advise other companies who have the same challenges as we did to choose SolidCAD, a supplier with a long history of technical and problem-solving experience, communication, resources and a lot of knowledge. Their staff has a lot of lived experience. Instead of wasting time trying to search online and solve workflow problems on your own, call on the expertise of SolidCAD.

This story was originally published by Troy Degroot on the Bluebeam Blog.

I’m a firm believer that every specialty contractor could benefit from implementing Bluebeam Revu in their everyday workflows. For this article, I’d like to highlight a concrete contractor’s position from bid to built.

There are a few important objectives we find in any construction project. I’d like to walk through how Revu meets those requirements. If you’re interested in learning more about how these can be done in Revu, have a look at “5 Ways Concrete Contractors Get the Most Out of Bluebeam Revu.”

Every company is different in how it approaches projects. In this article, I want to highlight the possibilities so you can see where Revu fits and what customizations may be required to make it fit your unique needs.

Let’s look at those project objectives.

From the first time you open the request for proposal (RFP), there are things a project manager starts to think about even before they open the drawings—and even more as the plans rollout.

Project Location: Do we have crews in the project location, or do we need to accommodate for travel expenses? While Revu may not have a “location cost” built into the available tools, it is possible to develop these. Perhaps you want to have a pulldown menu with specific cities or areas where you perform work regularly. Along with the locations in a pulldown, you could also associate a percentage markup to account for that area based on historical project data.

Pour Dates and Schedule: Do we have crews available to meet dates and project phases? For large development projects with phases, we can use the Spaces feature in Revu. Simply draw a Space shape around an area of work and name it “Phase II.” By doing so all the slabs, curbs, etc., will be categorized in the markups list under the Phase name. This makes it easier to allocate crews, materials and equipment based on the specific requirements of each phase. We can also track the progress using the built-in Status column where crews can mark each day’s progress on what slabs, walls or foundations were completed.

Equipment Required: Just like labor availability, we need to consider equipment availability for things like forms, trucks, curb or cross pan machines. Creating custom tools in Revu, you can place a symbol within a “Phase” indicating what equipment is required. You can even allocate a rental price per day for the equipment cost estimate.

Estimate: There are great measurement tools included in Revu allowing you to calculate area of slabs, volume of isolated pad footings or linear footage of strip footings. The versatility of Revu and our ability to customize tools opens the door to personalizing your markups and what data is generated. We can differentiate types of pours by color, linestyle and hatch patterns, or even add labels to display a description right on the drawing. We can also add parameters like design mix, hand vs. machine, or whether fiber mesh or WWF is required. In some cases, we could even estimate the rebar required or the number of trucks need to be scheduled based on cubic yards.

Finish Requirements: We need a clear understanding of finishes like construction/control joint layouts, stamped design, smooth or broomed, color stained or saw cut requirements. Applying different colors or hatch patterns to the markups will clearly identify those areas in a clear and visual way for the estimator and the crew in the field. A custom line tool representing saw cuts allows you to trace them on plan and quickly apply labor and equipment costs based on a linear footage collected in the markups.

QA/QC: As a final walk through you can do a punch list noting any damage cause by other trades. You can easily incorporate images or video documenting these damages and what it will cost to fix them.

Revisions and Scope Changes: Every project has delays for weather, site and utility prep. Often projects have design changes as well and we need to not only stay current but also track and communicate scope changes. These can often change cost and pricing as the scope begins to creep after the original estimate. Revu also has tools called Document Compare and Overlay Pages that will look at two drawings and quickly point out the differences. Document Compare is going to automatically draw clouds around all the changes. Overlay Pages is like the old light tables we used to place physical drawings over one another and see what was different. After finding the changes, your takeoff markups can quickly be stretched or moved rather than starting over. At that point, you have tangible evidence of scope changes for cost updates.

After reading these objectives and possibilities, you could have one of three responses. One, this article helped evaluate Bluebeam Revu as a solution. Two, you already use Revu, but the article sparked ideas on how your current use could improve. Or three, we confirmed you’re already getting the most out of your software investment.

Many of our customers desire the ability to transform Civil 3D data between coordinate systems. This was challenging or impossible…until now! Read on…

It is available for Civil 3D 2019-2022. Read more about this extension here.

The Autodesk® PPK Survey Extension 2022 for Civil 3D® provides an interface for importing GPS data (in RINEX format) for analysis, reporting, and converting it to coordinate geometry points in an Autodesk Civil 3D drawing. Once installed, users can access the Autodesk PPK Survey Extension 2022 for Civil 3D commands via the Autodesk Civil 3D Toolbox.

Under COGO Points Transformation Tools:

Under GNSS Data Processing:

In my previous blog, I explained how Navisworks can complement Plant 3D.

Now I will show you how to enable some Navisworks features directly within Plant 3D, or any AutoCAD based products. With this feature enabled the user can export a Navisworks (NWC) file directly from within AutoCAD. They will also have the option to manage the Navisworks export settings.

For this example, I will be using AutoCAD Plant 3D 2021 and Navisworks Manage 2021. If you do not have access to Navisworks you can download the Navisworks exporters from Autodesk directly.

Here is the link: Navisworks 3D Viewer Free Download | Navisworks Freedom (autodesk.com)

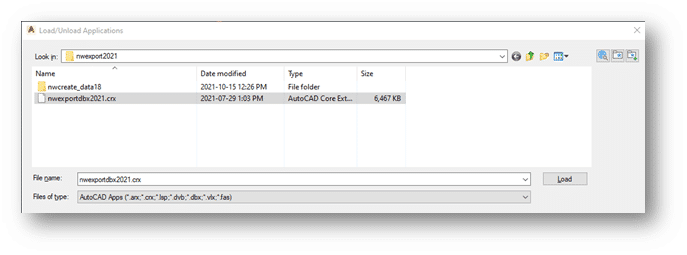

Loading the Plug-in in AutoCAD

1) Open or create a new DWG in AutoCAD.

2) In the Command line, type APPLOAD

3) Navigate to: C:\ProgramData\Autodesk\ApplicationPlugins\autocad_exporter2021_x64.Addin.bundle\nwexport2021

4) Select crx

5) Click on Load

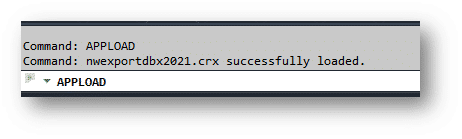

6) It will inform you if the Plug-In was successfully loaded.

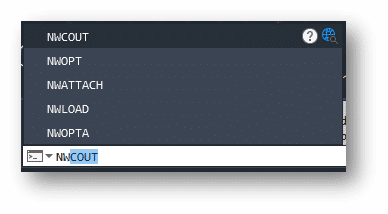

7) To test it, start typing NW in the command line. A new set of Navisworks commands should be available.

8) To export DWG contents, simply type NWCOUT and save the file.

Adding the Navisworks Menu in AutoCAD

With AutoCAD or a DWG open, type CUILOAD in the command line:

1) Click on Browse

2) Navigate to: C:\ProgramData\Autodesk\ApplicationPlugins\autocad_exporter2021_x64.Addin.bundle\nwexport2021\nwcreate_data18

3) Change the File type to “Legacy Menu Files”

4) Select mnu and click open.

5) Click on Load

6) Close the CUI dialog box. If you get a warning message, it is ok to proceed.

If you would like to learn more, Navisworks training is available as a supplementary course to SolidCAD’s Plant 3D course curriculum. Please contact training@solidcad.ca

Many “free“ content management solutions are available in the market today, such as SharePoint, Box, Network Shares, and even USB external drives. Organizations recognize the need to capture their electronic documents online and use these tools to fill the need. While providing basic functionality, “free“ applications can cost your business more money and time than a dedicated engineering document management system (EDMS).

While seeming to be a cost-effective solution, the reality is these “free” tools are missing a considerable amount of standard EDMS functionality. Here are just a few examples:

This lack of features can cost money to your organization and cause lost knowledge with staffing turnover and retirement.

Where “Free” Document Management Tools can work and their Limitations

Some businesses can have success using document management solutions such as SharePoint, Box, and other file share applications if they fall into the following categories:

These tools tend to work as sizeable digital filing cabinets, allowing groups to share and save documents in an accessible space and provide the following benefits for non-technical documents:

Where “Free” Document Management Tools Fail Engineering Requirements

While these “free” tools fill a niche role, they do not provide a complete solution required by an Enterprise-class organization that requires structured, controllable document management.

A “free” tool can assist organizations that utilize a basic linear workflow for generic documents, but technical documents and drawings require a malleable workflow. Technical documents usually are highly regulated with a control process in place.

Technical documentation also comes with the following challenges:

These factors make engineering documentation tough to manage, access, and control. When you add in other systems, such as a CMMS tool, it is challenging to monitor this information within the limitations of a free tool.

Getting this wrong can have a significant impact and reverberating effects throughout multiple teams. In document-heavy facilities (i.e., power plants, factories, etc.), technical information must be accurate and available to avoid downtime and maintenance issues, leading to lost revenue. Businesses trying to shoehorn these free tools into their typically experience the following problems:

The True Value of Meridian EDMS

A robust engineering document management solution (EDMS) like Meridian is required to help organizations manage their technical data and avoid the pitfalls of “free” tools. While having an initial higher cost, EDMS solutions provide a considerable value when looking at the overall picture. Here are a few benefits gained by using a dedicated EDMS:

1) Document Exchange

Larger projects bring the challenge of sharing documents with multiple departments and teams. These documents can be lost or delayed when being pushed through the review cycle. An example of this is an AutoCAD file with external references. Drawings referenced by the target document can be ignored or lost during a typical workflow unless tightly tracked throughout the process.

Meridian solves this issue by tracking these secondary technical documents with built-in functionality. Free tools such as network shares or Dropbox do not cover these scenarios, leading to lost or duplicated work.

2) Extra IT Maintenance Costs

While a “free” tool can seem cost-effective, it often strains IT resources assigned to manage them. Typically, the IT resource tasked with maintaining this tool is responsible for many other systems and lacks the proper training.

The Meridian SaaS offering provides all maintenance, support, and upgrades which removes the added workload from your IT resources.

3) Work Order Efficiency

While “free” tools can help a smaller business execute on work orders, they become a hindrance to a larger organization with multiple teams and facilities. Work orders can be challenging to locate across multiple disparate systems with inadequate search tools, which can lead to the following:

With a dedicated EDMS like Meridian, your organization can refer to a single source of truth that features purpose-built document control. Technicians will gain access to the latest document version that is found easily using robust search capabilities. All technical documents related to an asset can be located quickly via a tag scanner or the surrounding metadata via the advanced search. Streamlining this process will have an immediate impact on work order costs and resource availability.

4) Lower Operating Costs

Using “free” tools alongside legacy pen and paper document solutions incur costs associated with printing and logistics. When you need to get a hard copy into the hands of a critical resource on time, this can impact your budget. Not only can this cost your business money, but it also wastes effort if the package does not contain all the required documents.

The Meridian solution will allow your teams to move critical data into a single system with high online availability. Moving to an EDMS will allow your resources to access the latest complete document packages on many IoT platforms (i.e., mobile devices, tablets, PCs). Manual labor is heavily reduced via the automation capability of the tool, saving many hours in labor costs.

Sometimes “Free” is Expensive

The actual cost of a “free” or legacy tool can surprise an organization. By not using a purpose-built application to manage your technical documents, you can end up costing your business time, efficiency, and money in the big picture.

If your business is interested in unlocking the power of a dedicated EDMS, don’t hesitate to get in touch with the SolidCAD Meridian team.

We are excited to share with you the highlights of the latest Autodesk Desktop Connector update!

Enhancements are:

There have been significant changes to folder sharing. If you have folders shared, it is recommended to educate yourself on the new behavior.

The new behaviour is outlined here and here.

For more information, visit this link.