This story was originally published by on the Bluebeam Blog.

With smart PDFs now being generated as part of bid packages thanks to a variety of digital tools within the marketplace, end–users can now use technology to boost the visual appeal, accuracy, and overall value of bid packages.

“Bluebeam Revu can actually make use of those smart PDFs by making sure that it allows estimators to take off quantities accurately,” said Deepak Maini, a qualified mechanical engineer with two decades of experience. “The tools that you’ve got available in Bluebeam Revu, the accuracy of picking regions, the accuracy of visually searching items, and the standardization potential make it a great asset to making a successful bid package.”

Three keys to a successful bid

- Accuracy of the scale of the sheet

- The right set of customizable and standardized digital tools

- Accurate cost values associated with materials and labor

Quantity takeoffs and accuracy

Now a noted guest lecturer at the University of Technology Sydney (UTS) and University of New South Wales (UNSW), Maini, the current national technical manager for Cadgroup Australia, advocates for paperless bid packages and credits Revu as a crucial piece of the puzzle.

“In the Australia-New Zealand market, and actually in the global market as a whole, the climate is very competitive,” Maini said. “The process of taking off quantities within today’s market needs to be accurate and needs to be fast. And that’s where Bluebeam Revu plays a massive role. With it, the estimator can take off quantities on one job and then quickly get onto the next job without wasting too much time.”

“There’s absolutely no comparison between Revu and paper,” Maini continued. “We are talking about projects going in hundreds of millions of dollars and billions of dollars as well, which means that you’ve got these PDF sheets getting delivered to you, which are not two or three sheets. You’ve got 100-150 sheets getting delivered and that’s why taking off quantities using an accurate process is really important.”

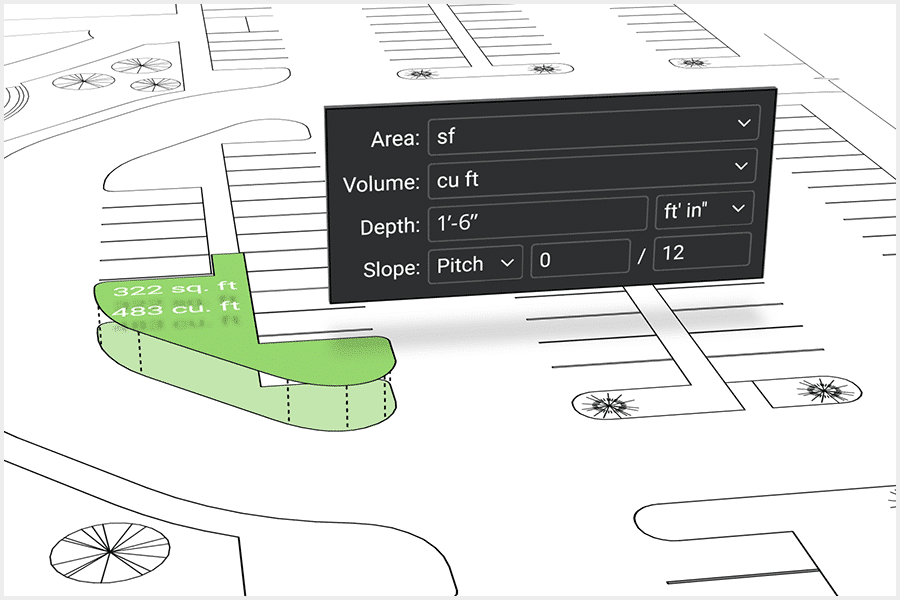

Ensuring scale can also be achieved within the sophisticated calibration capabilities in Revu. This is crucial when receiving documents as you don’t have to rely on the imagery to be accurate in scale, which could be a huge issue for estimation.

“In Revu, we calibrate the sheet and we find out what scale the objects are at, and then when we are taking off the quantities, it ensures that we use the right scale and we get the right measurements,” Deepak said.

Standardizing

Being able to consistently takeoff accurate quantities is essential to completing bid packages in a timely and accurate manner.

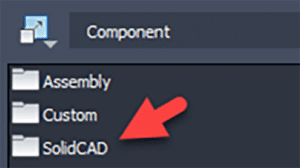

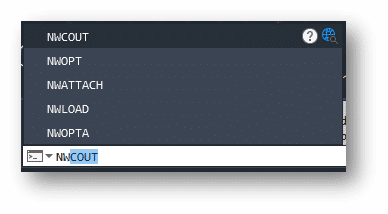

“This is again where Bluebeam Revu is absolutely fantastic,” Maini said. “I create certain specialized and takeoff tools, I can then have them sitting in my own custom toolset, and then I can distribute the toolset within my own team, which means that everybody who’s taking off the quantities will have the same display of quantities. ”

Cost values can also be plugged into Revu, allowing instant dollar projections for the project. “As you take off the quantities, it gives you the dollar value of that quantity right there in front of you,” Maini said. “You can have that displayed as a table on the sheet, which means that you can straight away find out how much it’s going to cost you.”

The ability within the digital tools in Revu to drive accuracy and consistency among estimators allows firms the flexibility to more accurately staff projects, without the risk of lesser experienced estimators using a process of their own, which might hinder the accuracy of the quantity takeoffs and the success of the bid as a whole.