Success Stories

Mega Mold International Inc.

Mega Mold produces the best world class tooling for the automotive, industrial and consumer markets. For over 28 years, their team of specialists deliver tooling that is superior in class for cycle time and part quality in all aspects of plastic injection mold designs.

Mega Mold provides their customers quality services including:

- Standard Injection

- Multi-shot Rotary

- Stack Molds

- Aluminum Production Tools

- Compression Tools

- Proto-type Tooling

- Gas Assist

- Insert Molding

Mega Mold and members of the SolidCAD team have had a long-lasting partnership that predates SolidCAD and began over 20 years ago. As a loyal and legacy customer, SolidCAD’s advanced manufacturing team has always provided the knowledge and assistance throughout Mega Mold’s growth.

Improving efficiency with Fusion 360 Probing

The Challenge

As a leader in the tooling industry, Mega Mold needed an advanced solution with powerful capabilities that could check features during the machining process, automate tedious tasks and make decisions. More specifically, they were looking for an easy way to help verify workpiece accuracy and help make their machining process more efficient. Mega Mold knew that they needed a solution that would reduce machine time, rework, and unnecessary setup time.

The Solution

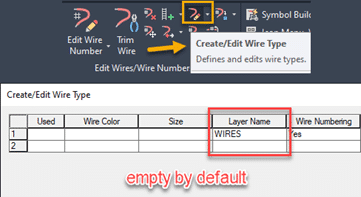

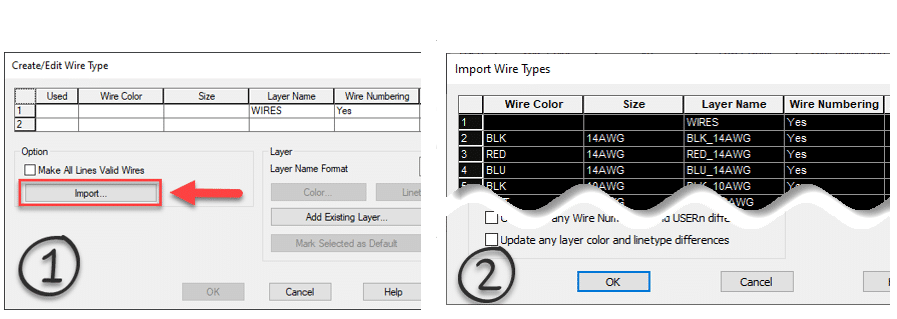

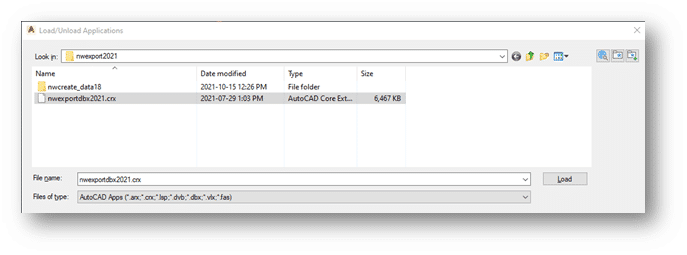

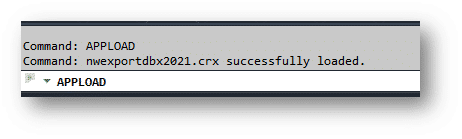

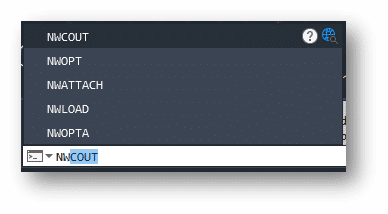

Mega Mold always looked to have a partner with a localized team, that could easily support them on-site during any implementation and provide continued education to their employees. Knowing that SolidCAD could provide them just that, they offered an analysis of their current machining workflow and identified that Autodesk’s Fusion 360 with the Machining Extension was needed to eliminate their challenge and speed up machine times.

SolidCAD provided implementation services, including ongoing support and training for the software so that all members of the team understood Fusion 360’s functionalities.

The Results

Understanding that Mega Mold needed a quick solution, SolidCAD worked promptly with Mega Mold’s Managers and Operators to fulfill their requirement and introduce Fusion 360 into their process in only 5-6 hours.

Fusion 360’s capabilities allowed them to check their workpiece accuracy using their current machine probe and easily access advanced on-machine verification.

This implementation reduced hours that were often spent on unnecessary set-up times. They quickly realized that since the job was automatically verified within tolerance before removing it from the machine table, they could produce high quality finished molds and mold components without the need for a post machine inspection, removing any inaccuracies, and allowing them to meet client deadlines faster.

SolidCAD continues to support Mega Mold during the introduction of their process and provide on-going training for their employees.

Testimonial

“We choose SolidCAD because they are a partner who understands our business. They always made sure to be responsive to our time, budget and needs. Whenever we needed on-site support, even during a pandemic, they were there to assist us and guarantee we could get the job done. We continue to have a great relationship with their team and trust them to provide the support and expertise for our machining processes.”

– David Thibert,

President at Mega Mold International Inc.

Products & Services Used

- Fusion 360 Probing

- Implementation and Training

- Support